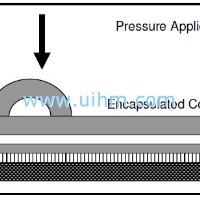

Objective Heating end of a stainless steel handle with a plastic sleeve coated with heat adhesive for a bonding application

Material 1” (25mm) OD stainless steel handle 0.30” (7.6) thick covered with a plastic sleeve that is coated with a heat adhesive between the tube & plastic cover

Temperature 250 ºF (121 ºC)

Frequency 170 kHz

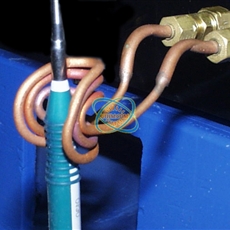

Equipment • Power of 5kW induction heating system, equipped with a remote workhead containing one 1.2μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn helical coil is used to heat the handle assembly.

The assembly is placed in the coil and heat is applied for 10 seconds at the end of the handle to reach the required

temperature of 250 ºF (121 ºC) to adhere the plastic sleeve to the handle.

Results/Benefits Induction heating provides:

• Increased production rates

• Increased energy savings

• Highly accurate placement of heat, no effect to surrounding components

• Even distribution of heating

Related

© Copyright 2025. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment