Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.

Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.Material 3" by 10.25" section of a 21" solar panel shingle

Temperature 140 ºC

Frequency 176 kHz

Equipment An UM-06A-UHF power supply equipped with a remote heat station containing one 0.66mF capacitor.

A custom-made coil: 4 turns of 1/4" x 1/2" rectangular copper tubing, measuring 24" by 2 1/4".

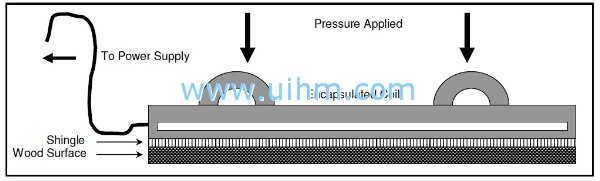

Process Stationary heating - with the coil located on the topside of the sample - was utilized to achieve uniform melt and adhesion.

The shingles were overlapped according to requirements and placed on wood to simulate the installation on a roofing

surface. In addition, pressure was applied by pressing the water-cooled coil against the shingle to facilitate the bonding

(illustration). Tests are performed at several time-voltage settings.

Results Tests resulted in excellent bond formation with the absence of encapsulant bubbling and only slight surface texture change.

Newest Comment

No Comment

Post Comment