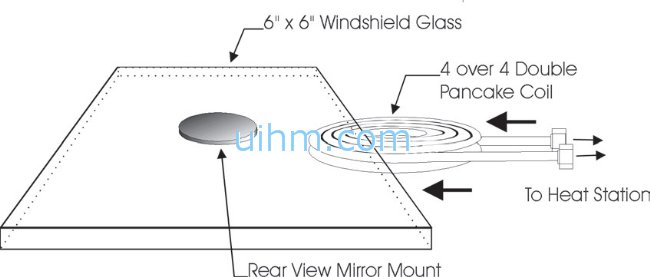

Objective Heat steel, stainless steel, nickel chrome rear view mirror brackets and adhesive are to be bonded onto a section of windshield glass.

Material Steel, Stainless Steel, and Nickel Chrome rear view mirror brackets measuring 1"(25.4mm) in diameter and 1/8" (3.2mm) thick. A 6" by 6"(152.4mm x 152.4mm) section of windshield glass.

Temperature 300°F(148.9ºC)

Frequency 455 kHz

Equipment

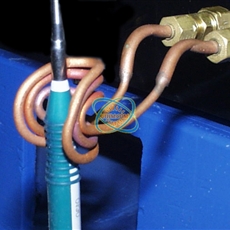

• 6kW induction heating system equipped with a remote workhead.

• 6kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

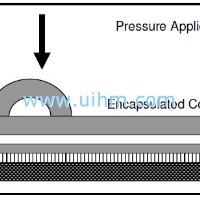

Process A unique four over four double wound pancake coil is used for the bonding application. A temperature of 300°F(148.9ºC) is applied for 5 seconds to bond the adhesive to the mirror bracket and glass.

Results/Benefits

Induction heating provides:

Induction heating provides:

• Provide high strength bond upon cooling

• Low temperature avoids damage to components

• Minimal energy and time

Newest Comment

No Comment

Post Comment