-

Keywords"n",total 3020 records

-

induction melting aluminum for casting

Objective Heating a graphite crucible to 1292F (700C) to melt aluminum to liquid form for a casting applicationMaterial 9.8” (250mm) OD, 22.4” (570mm) long, 0.7” (17.5mm) thick Graphite crucible, approx. 92.5lb (42kg) of aluminumTemperature 1292 F (700C…

Date:2008/02/03

-

induction melting lead ingots

Melting lead ingots Objective Melting 30 lb(13.6 kg) & 60 lb(27.2 kg) lead ingots to formbattery posts & connectorsMaterial 30 lb(13.6 kg) & 60 lb(27.2 kg) lead ingots and 5” (12.7cm) IDZircar Ceramic Alumina tubeTemperature 620 FFrequency 10 …

Date:2008/02/03

-

induction crucible melting

Crucible melting Objective Heat to melting point various materials in a nitrogen atmosphere in a graphite or molybdenum crucible.Material Magnesium fluoride, tantalum pentoxide, aluminum, yttrium fluoride, germanium, hafnium or titanium dioxide and a Pyrex…

Date:2008/02/03

-

induction bonding plastic handle to knife

Bonding plastic handle to knife Objective Bonding handle of a stainless steel surgical knife into a plastic handle Material Plastic tool handle, 0.125” (3.18mm) diameter steel knife Temperature 450 F (232 C) Frequency 390 kHz Equipment • Power of…

Date:2008/02/03

-

induction heating graphite susceptor

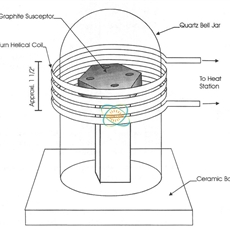

Heating Graphite Susceptor Heating Graphite SusceptorObjectiveTo Heat a graphite susceptor to 1100C in an inert atmosphere of Nitrogen and Hydrogen. The susceptor is to be used for metal oxide chemical vapor deposition (MOCVD) crystal growth experiments. V…

Date:2008/02/03

-

induction heating light bulbs

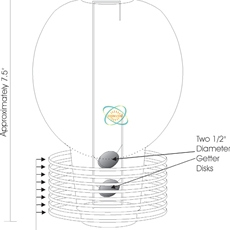

Objective To heat two 0.5″ getters to a red glow inside a light bulb in order to fire the getters within 8 seconds. Presently the bulbs are lowered onto an eight station turnstile with an index time of 8 seconds. Material Metal Halide Lamp containing …

Date:2007/04/03

-

levitation induction melting system

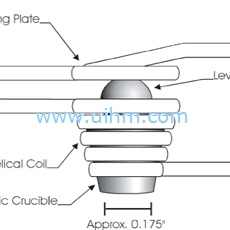

Objective Design a modular electromagnetic levitor (MEL) to aid in the study of RF systems used to process metals in the microgravity of space. Nickel and copper are melted and levitated. A reliable system is to be developed to provide repeatable performan…

Date:2007/04/03

-

induction hardening teeth of gear

Objective Hardening teeth on a steel motorcycle gear to a hardness of 48 – 55 HRC Material Carbon steel gear 6.9” (175mm) diameter Temperature 2000 F ( 1093 C) Frequency 78 kHz Equipment •Power of 90 kW induction heating system, equipped with a remo…

Date:2007/04/03

-

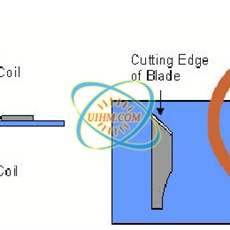

induction hardening surgical blades

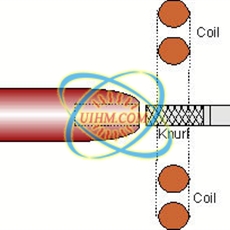

Objective To quickly heat a steel surgical blade to 2000F (1093C) within 2 seconds so as to harden the blade edge. Material Stainless steel surgical blades, temperature sensing paint Temperature 2000F (1093C) Frequency 339kHz Equipment Power of 6kW ind…

Date:2007/04/03

-

how to choose induction heaters

Induction heating by high frequency Induction heaters output current through the coil generates an alternating magnetic field, through the induction loop on the formation of eddy currents in the metal workpiece, so that the rapid heating, and induction loo…

Date:2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.