-

Keywords"The",total 43 records

-

high-frequency induction surface hardening working for The steel

induction hardening HDTV rotating bodies made with the rotation of hardened parts. Long parts hardened inductor in series with the movement along the axis of the member. Cooling the workpiece immediately after the heating is performed by jets of water or a…

Date:2013/04/08

-

induction Thermocouple brazing 25kw

Induction brazing and soldering are processes that take advantage of induction heatings ability to deliver rapid localized heating to a particular region of a part.induction Thermocouple Brazing 25kW

Date:2003/04/01

-

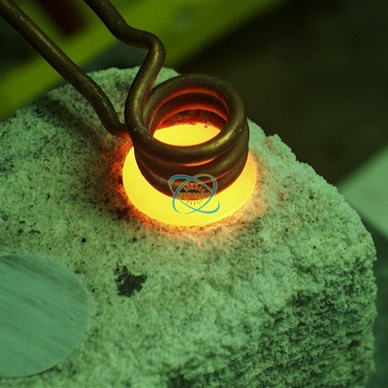

induction brazing Thermocouples

Induction brazing and soldering are processes that take advantage of induction heatings ability to deliver rapid localized heating to a particular region of a part.induction Brazing Thermocouples

Date:2003/04/01

-

anoTher u shape induction coils for heating saw teeth

another U shape induction coils for heating saw teeth Base Induction Coil Design and Theory Induction Coil Design and Fabrication

Date:2010/08/30

-

induction brazing composite bottom of The pot

induction brazing composite bottom of the pot_1 induction brazing composite bottom of the pot_4 induction brazing composite bottom of the pot_3 induction brazing composite bottom of the pot_2

Date:2010/04/30

-

induction heating in magnetically induced hyperThermia for cancer

Magnetically Induced Hyperthermia for Cancer Therapy TANG Jintian,et al. Abstract: The defects in the traditional heating methods such as ultrasound,microwave and radio frequency limit the development of cancer hyperthermia. However,magneticall…

Date:2010/04/30

-

this illustration shows how The connecting sleeve of a plate heat exchanger is inductively brazed on

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

Date:2010/04/30

-

Theory and examples of ac resonant charging,

RESONANT CHARGING The connection of a Tank capacitor across an inductively ballasted supply creates a resonant circuit. The resonant frequency of this arrangement is determined by the valu…

Date:2009/10/01

-

research The heating effects

Research the heating effects Objective Heating stainless steel disc & tantalum disc to 1400F (760C)Material Stainless steel and tantalum discs approx 1/2” (12.7mm) diameter. End product is radioactivity counting plateTemperature 1400 F (760C)Frequency…

Date:2008/08/03

-

induction heat The end of catalytic converter

Heat the end of catalytic converter Objective Heat the end of lorry catalytic converter exhaust system. The assembly must be held at target temperature for 200 hours, whilst the assembly is vibrated to test the weld strength.Material SteelTemperature 842 –…

Date:2008/08/03

© Copyright 2025. uihm.com All Rights Reserved.