-

Keywords"welder brazing",total 336 records

-

brazing equipment of diamond tools

Brazing is the most reliable method of joining diamond to metals. It is also the most widely used and one of the areas where processes are held as trade secrets in most companies. This paper attempts to provide a general overview of brazing diamonds, and a…

Date:2013/06/02

-

what is induction vacuum brazing

Brazing especially vacuum brazing is highly sophisticated and specialized joining process as compared to welding and other conventional methods of joining. The brazing process is deployed when component joining becomes difficult by using the conventional m…

Date:2013/05/16

-

tubular induction brazing wires

Made from seamless tubular wire This ensures consistent flux to wire ratio and is especially important in the fabrication of pre-forms.Competitors products are made from folded sheets and flux may be lost during fabrication or during transport.Our flux cor…

Date:2013/05/16

-

cadmium in silver soldering or brazing

Silver (hard) soldering or brazing is a very versatile means of making joints by using a fusible alloy as a filler material between similar or dissimilar parent materials.Temperatures above 620C are applied, usually by handheld flame torch or another heati…

Date:2013/05/16

-

induction vacuum brazing

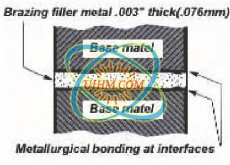

5. KEY PARAMETERS OF BRAZINGThe quality of brazed joint depends strongly on the combination of filler and base materials and the processing conditions that are used. Other factors which influence the joints are condition of the solid surfaces i.e. nature o…

Date:2013/04/08

-

induction brazing turbine blades

Process The UIHM ABS Mark 2 with a vacuum level of <510-4 torr was used for the testing. A specially designed induction coil was used to provide optimal heating (approximately 80% energy efficiency) to the braze joint area. The temperature of the joint …

Date:2013/04/08

© Copyright 2025. uihm.com All Rights Reserved.