-

Keywords"steel",total 554 records

-

induction forming steel rod

induction heating technology is widely used in various of workinduction forming steel rod

Date:2013/07/29

-

induction hardening steel ring

Induction hardening is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is u…

Date:2013/07/29

-

induction brazing steel rod

Induction Brazing temperature can be controlled from 500 C to 1800 C for most of the brazing applications.UIHM induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke.indu…

Date:2013/07/29

-

induction forging rod steel

A superior alternative to furnace heating, induction heating provides faster, more efficient heat in forging applications. The process relies on electrical currents to produce heat within the part that remains confined to precisely targeted areas. High pow…

Date:2013/07/29

-

induction forging steel horse shoes

Objective To heat a strip of 1025 steel to 1800 oF prior to a forging process for the production of horse shoes. Presently, blanks are cut and heated in a gas fired oven and then forged in the press. With an induction coil in place, the steel would be fed …

Date:2013/07/29

-

induction heating steel rod ,steel bar with square induction coil

Induction coil is very important for the induction heating system, different shape, size, material, turns of induction coil will bring different output frequency or output power.The biggest disadvantage of induction heating is still the induction coil.indu…

Date:2013/07/13

-

induction curing adhesive for steel motor shaft

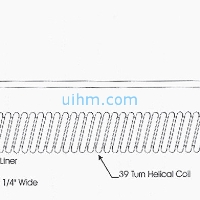

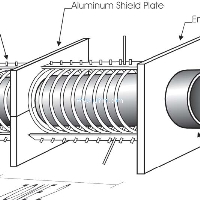

Objective: induction Curing Adhesive for the internal wall (inner interface) of a steel motor shaft to bond electronic stress/strain gauges into place.Material: Steel shaft measuring 6.65" (168.9mm) OD, 5.5"(139.7mm) ID and 70" (1.8m) long. …

Date:2013/07/05

-

high frequency induction brazing welding steel bar

High frequency induction brazing welding steel barInduction braze welding head, Phillips head welding machine can be used for brazing alloy welding tools, for example: boring machine cutter, coal drill, drill bits, air drill, alloy turning, milling, planer…

Date:2013/06/13

-

induction heating l shape steel with l shape induction coil

Objective: quick induction heating L shape steel for Material: stainless steelTemperature: 800 CFrequency: 60 KHzEquipment: UM-40AB-HFResults/Benefits: Induction heating provides:• Minimal contamination of conductive material during manufacturing• Quick …

Date:2013/06/09

-

induction brazing steel pipe gap

Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction …

Date:2013/05/31

© Copyright 2025. uihm.com All Rights Reserved.