-

Keywords"Induction Annealing",total 103 records

-

Induction Annealing for pot 3

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness.Applications: Annealing of Mi…

Date:2013/03/30

-

Induction Annealing for pot 4

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness.Applications: Annealing of Mi…

Date:2013/03/30

-

Induction Annealing for steel bar(steel rod)

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness. Applications: Annealing of M…

Date:2013/03/30

-

Induction Annealing for pots

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness.Applications: Annealing of Mi…

Date:2013/03/30

-

Induction Annealing for pot 5

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness.Applications: Annealing of Mi…

Date:2013/03/30

-

Induction Annealing treatment

Applications Stainless Steel / Aluminum Utensils All Cold Formed Steel Components. Stress Relieving. Post weld Annealing. Annealing of Copper tubes. Annealing of knife, blade ends. Shell Annealing. Annealing of wires. Continuous Annealing…

Date:2009/10/02

-

Induction Annealing stress relieving

STRESS RELIEVING,NORMALISING AND ANNEALINGStress RelievingStress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling and…

Date:2007/04/03

-

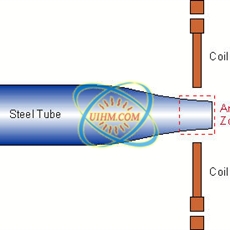

Induction Annealing steel tubes

Objective To heat steel tubes to 2000 F (1093 C) in an inert atmosphere Material 0.1” (2.54mm) diameter stainless steel tube Temperature 2000 F Frequency 333 kHz Equipment • 10 kW induction heating system, equipped with a remote workhead containing…

Date:2006/10/02

-

Induction Annealing motor shaft

Objective Annealing the end of a steel hydraulic motor shaft prior to machining Material .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end Temperature 1350 F (732 C) Frequency 359 kHz Equipment • UM-06A-UHF induction heating…

Date:2006/10/02

-

Induction Annealing aluminum tubing

Objective Annealing aluminum fuel tank fill neck to 650 F (343 C) Material Aluminum fill neck 2.5” (63.5mm) diameter, 14” (35.5cm) long Temperature 650 F (343 C) Frequency 85 kHz Equipment • 40kW induction heating system, equipped with a remote work…

Date:2006/10/02

© Copyright 2025. uihm.com All Rights Reserved.