-

Keywords"heat",total 1024 records

-

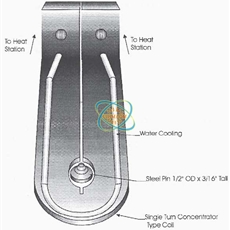

induction heat television picture tube glass

Heat Television Picture Tube Glass Objective: The incorporation of solid state RF induction heating into the television picture tube industry, specifically the insertion of attachment pins into the already formed picture tube glass panel. Four pins are…

Date:2008/02/03

-

heat treatment with induction heating of within pipes

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat-trea…

Date:2008/02/03

-

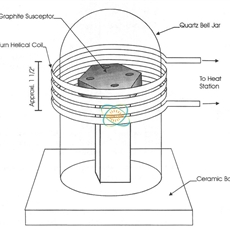

induction heating graphite susceptor

Heating Graphite Susceptor Heating Graphite SusceptorObjectiveTo Heat a graphite susceptor to 1100C in an inert atmosphere of Nitrogen and Hydrogen. The susceptor is to be used for metal oxide chemical vapor deposition (MOCVD) crystal growth experiments. V…

Date:2008/02/03

-

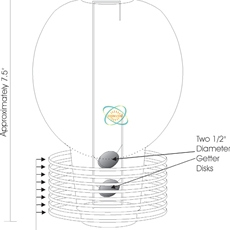

induction heating light bulbs

Objective To heat two 0.5″ getters to a red glow inside a light bulb in order to fire the getters within 8 seconds. Presently the bulbs are lowered onto an eight station turnstile with an index time of 8 seconds. Material Metal Halide Lamp containing …

Date:2007/04/03

-

how to choose induction heaters

Induction heating by high frequency Induction heaters output current through the coil generates an alternating magnetic field, through the induction loop on the formation of eddy currents in the metal workpiece, so that the rapid heating, and induction loo…

Date:2007/04/03

-

igbt induction heater profiles

MF IGBT power transistor module is in the early 1990s, foreign advanced technology, developed a new type of variable frequency induction heating equipment, won the “National New Product Award”. Wide range of applied high-capacity, high efficiency melting…

Date:2007/04/03

-

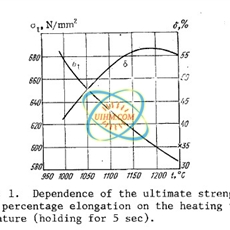

steel induction heat treatment

Overall heat treatment is heating the whole piece, then the appropriate speed cooling, to change its overall mechanical properties of the metal heat treatment process. Roughly the overall heat treatment of steel annealing, normalizing, quenching and temper…

Date:2007/04/03

-

induction heat treating

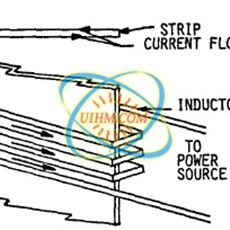

Induction heating has been used extensively for heat treating processes in a variety of metalworking applications.Some of these applications are associated with discrete parts such as shafts, bearings, gears, and hubs. Here, the most common processes are h…

Date:2007/04/03

-

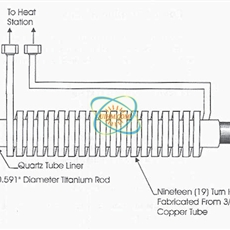

induction preheating titanium rods

Objective To heat titanium rod blanks prior to forging into a turbine blade. Material Titanium rod blanks 0.591″(15.01mm) OD by 11.8″(299.7mm) long Temperature 2030F(1110C) Frequency 64 kHz Equipment • Power of 45kW induction heating system equipped…

Date:2007/04/03

-

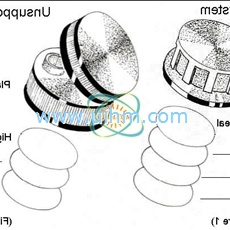

cap sealing with induction heating

Objective An induction heater is used to heat a polymer laminated aluminum foil in 0.5 to 2.0 seconds. The heat produced in the aluminum foil melts the polymer that bonds to the neck of a plastic container.Material Aluminum foil, polyethylene, polypropylen…

Date:2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.