Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.

Induction Brazing temperature can be controlled from 500 C to 1800 C for most of the brazing applications.

For processes, which involve medium to high production runs of the same parts, an automated part handling system is often utilized to further improve consistency and maximize productivity. For the most part, induction brazing and soldering is done in an open-air environment but it can also be done in a controlled atmosphere when necessary to keep the parts completely clean and free of oxidation. Induction brazing generally works best with two pieces of similar metal. Dissimilar metals can also be joined by induction heating but they require special attention and techniques. This is due to differences in the materials' resistivity, relative magnetic permeability and coefficients of thermal expansion.

Applications:

Induction Brazing temperature can be controlled from 500 C to 1800 C for most of the brazing applications.

UIHM induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke.

Features:

- Controlled atmosphere brazing is possible

- Highly adaptable for automation

- Eco-friendly due to noiseless and flameless operation

- No statutory approvals required

- Lesser risk involved compared to conventional methods

- Uniform heating at desired area provides even flow of filler metal

- Lesser brazing cost comparing to conventional methods

- Application Specific

- Auto or manual mode operation

- Improved power factor

- Strong and ductile joints

- Suitable for dissimilar materials

- Tropicalised design

- Compact size

Benefits

There are specific reasons to use induction heating for industrial brazing. These include selective heating, better joint quality, reduced oxidation and acid cleaning, faster heating cycles, more consistent results and suitability for large volume production.Selective heating

Induction heating can be targeted to provide heat to very small areas within tight production tolerances. Only those areas of the part within close proximity to the joint are heated; the rest of the part is not affected. Since there is no direct contact with the part, there is no opportunity for breakage. The life of the fixturing is substantially increased because problems due to repeated exposure to heat (such as distortion and metal fatigue) are eliminated. This advantage becomes particularly important with high-temperaturebrazing processes.

With efficient coil design, careful fixturing and consistent part placement, it is possible to simultaneously provide heat in different areas of the same partBetter quality joints

Induction heating produces clean, leak proof joints by preventing the filler from flowing in areas that it shouldn't. This ability to create clean and controllable joints is one of the reasons that induction brazing is being used extensively for high-precision, high-reliability applications.Reduced oxidation and cleaning

Flame heating in a normal atmosphere causes oxidation, scaling and carbon build up on the parts. To clean the parts, applications of joint-weakening flux and expensive acid cleaning baths have traditionally been required. Batch vacuum furnaces solve these problems, but have significant limitations of their own because of their large size, poor efficiency and lack of quality control. Brazing with induction reduces both oxidation and costly cleaning requirements, especially when a rapid cool-down cycle is used.Fast heating cycles

Because the induction heating cycle is very short in comparison to flame brazing, more parts can be processed in the same amount of time, and less heat is released to the surrounding environment. “An induction brazing system quickly delivers highly localized heat to minimize part warpage and distortion. Brazing in a controlled vacuum or in an inert protective atmosphere can significantly improve overall part quality and eliminate costly part cleaning procedures”Consistent results

Induction brazing is a very repeatable process because variables such as time, temperature, alloy, fixturing, and part positioning are very controllable. The internal power supply of the RF power supply can be used to control cycle time, and temperature control can be accomplished with pyrometers, visual temperature sensors or thermocouples.For processes, which involve medium to high production runs of the same parts, an automated part handling system is often utilized to further improve consistency and maximize productivity. For the most part, induction brazing and soldering is done in an open-air environment but it can also be done in a controlled atmosphere when necessary to keep the parts completely clean and free of oxidation. Induction brazing generally works best with two pieces of similar metal. Dissimilar metals can also be joined by induction heating but they require special attention and techniques. This is due to differences in the materials' resistivity, relative magnetic permeability and coefficients of thermal expansion.

Applications:

- Copper parts for compressors.

- Copper components of transformers.

- Brass components.

- Submersible pump rotors.

- Ring cable lugs.

- Aluminium component joints.

- Soldering of brass components.

- Steel components joints.

- Brazing of storage water heater Elements.

- Diamond tipped cutting tools.

- Carbide tipping of cutting tools.

- Optical Frame Brazing.

- Fuel pipe Brazing.

- Vacuum brazing of critical components.

- Brazing stainless steel orthodontic parts.

- Brazing of stainless steel to Brass.

- Rocker Pins.

- Hydraulic Hose.

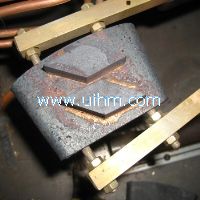

induction brazing diamond segment

induction brass soldering copper plate_2

induction brazing with special induction coil

induction brazing with multi induction coil

induction brazing stainless

induction brazing small bolt

induction brazing

induction brazing CTC knife by 200KW power supply

induction brazing shaft by UM-60AB-HF

induction brazing Fiber Interface by UM-05AB-UHF

induction brass soldering for copper bricks

induction brass soldering stator ends of wind driven generator within 2 seconds

ultra-high frequency induction brass soldering

round saw teeth (cemented carbide) by induction brazing

ultra-high frequency induction brazing stainless pipe and plate

induction brazing stainless plate

induction brazing stainless pipe

induction brazing stainless connector

induction brazing diamond segment Class: HF Induction Brazing

induction brazing diamond segment Class: HF Induction Brazing Intro: Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction

induction brass soldering copper plate_2 Class: HF Induction Brass Solder

induction brass soldering copper plate_2 Class: HF Induction Brass Solder Intro: induction brass soldering copper plate_2

induction brazing with special induction coil Class: HF Induction Brazing

induction brazing with special induction coil Class: HF Induction Brazing Intro: induction brazing with special induction coil

Press←or→to turn page