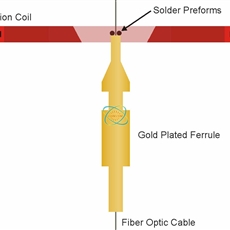

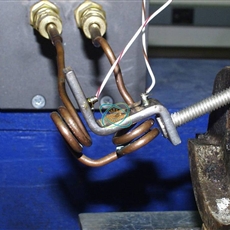

Induction soldering uses induction heating by high-frequency AC current in a surrounding copper coil. This induces currents in the part being soldered, which generates heat because of the higher resistance of a joint versus its surrounding metal (resistive heating).

These copper coils can be shaped to fit the joint more precisely. A filler metal (solder) is placed between the facing surfaces, and this solder melts at a fairly low temperature.

Fluxes are commonly used in induction soldering. This technique is particularly suited to continuously soldering, in which case these coils wrap around a cylinder or a pipe that needs to be soldered.

Some metals are easier to solder than others. Copper, silver, and gold are easy. Iron, mild steel and nickel are next in difficulty. Because of their thin, strong oxide films, stainless steel and aluminium are even more difficult to solder. Titanium, magnesium, cast irons, some high-carbon steels, ceramics, and graphite can be soldered but it involves a process similar to joining carbides: they are first plated with a suitable metallic element that induces interfacial bonding.

induction soldering for steel pan

ultra-high frequency induction heating glasses flames

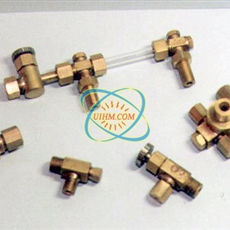

Induction Tin Soldering

Induction Tin Soldering

Induction Tin Soldering

Induction Tin Soldering

Induction Tin Soldering

Induction Tin Soldering

Induction Tin Soldering

Induction Tin Soldering

Induction

induction braze soldering machine application

induction heating for Sgmented wheel

induction heating saw teeth

Induction Silver Soldering

Induction Soldering copper wires

Induction Silver soldering with induction heating

Induction Soldering Co-axial Wire

induction soldering for steel pan Class: Induction Soldering

induction soldering for steel pan Class: Induction Soldering Intro: induction soldering for steel pan

ultra-high frequency induction heating glasses flames Class: Induction Soldering

ultra-high frequency induction heating glasses flames Class: Induction Soldering Intro: ultra-high frequency induction heating glasses flamesultra-high frequency induction heating glasses flame-1ultra-high frequency induction heating glasses flame

Induction Tin Soldering Class: Induction Soldering

Induction Tin Soldering Class: Induction Soldering Intro: Induction Tin Soldering