induction brazing air-condition compression engine Class: HF Induction Brazing

induction brazing air-condition compression engine Class: HF Induction Brazing Intro: air-condition compression engine brazing_1air-condition compression engine brazing_2air-condition compression engine brazing_

Induction Sintering copper powder Class: HF Induction Brazing

Induction Sintering copper powder Class: HF Induction Brazing Intro: Sintering copper powder Objective Sintering copper powder to a stainless steel shaftMaterial Steel shaft & shell assembly, approx 2” (50.8mm) diameter, 2” (50.8mm) tall, copper powderTemperature 1600 F (871 C)Frequency 54 kHzEquipment • Power o…

Induction Hermetically sealing glass Class: HF Induction Brazing

Induction Hermetically sealing glass Class: HF Induction Brazing Intro: Hermetically sealing glass Objective Provide a hermetic seal of glass enclosed resistor to a leadMaterial ResistorKovar rings, 0.1 inch (0.254cm) diameterGlass tube slightly larger than 0.1 inch (0.254cm) diameter, 0.5 (1.27) inch lengthMetal leadTemp…

Induction silver brazing with induction heating Class: HF Induction Brazing

Induction silver brazing with induction heating Class: HF Induction Brazing Intro: silver brazing with induction heatingInduction Silver brazing actually uses not pure silver, but instead a silver alloy containing nonferrous metal to bond two pieces of metal together. The process is typically used to join close-fitting parts that re…

Induction Bin Brazing Class: HF Induction Brazing

Induction Bin Brazing Class: HF Induction Brazing Intro: Bin Brazing Pin Brazing forms part of a technology developed in Sweden throughout the latter half of the 20th century by AGA. The purpose, for attaching current carrying cables to what were deemed Sensitive Substrate Materials, or in this case Railroa…

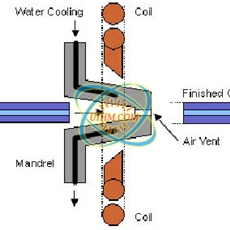

Induction Heating brass mandrel die Class: HF Induction Brass Solder

Induction Heating brass mandrel die Class: HF Induction Brass Solder Intro: Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller.Material materials, supplies involved in the applicationTemperature 400F (204C)Frequency 325kHzEquipment Power …

Induction Soldering brass Class: HF Induction Brass Solder

Induction Soldering brass Class: HF Induction Brass Solder Intro: Soldering brass Objective To solder a brass end cap to a series of copper tubesMaterial Preassembled heat exchanger with copper tubes and 2 brass end caps 2.36” (60mm) OD, 0.08” to 0.12” (2 to 3mm) thick at both ends, liquid solderTemperature 302F …

Induction Soldering brass and copper Class: HF Induction Brass Solder

Induction Soldering brass and copper Class: HF Induction Brass Solder Intro: Soldering brass and copper Objective To heat brass and copper for soldering application on medical equipmentMaterial Brass ring, brass and copper pieces 5.11” (130mm) long, 4.3” (110mm) OD & 0.3” (7mm) at thickest point and solder ringsTemperat…

Induction Soldering brass rings Class: HF Induction Brass Solder

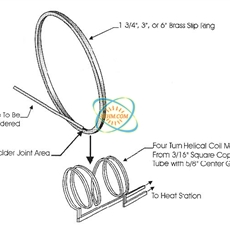

Induction Soldering brass rings Class: HF Induction Brass Solder Intro: Soldering brass rings Objective: To heat 1 3/4, 3 and 6 diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick…

Induction Soldering Brass Bellows Assembly Class: HF Induction Brass Solder

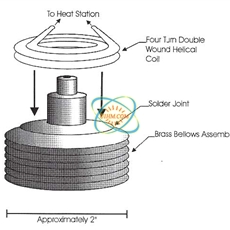

Induction Soldering Brass Bellows Assembly Class: HF Induction Brass Solder Intro: Soldering Brass Bellows Assembly Objective: To heat a brass bellows and end cap assembly to 450F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality sol…