Induction Brazing Brass Fitting to Copper Air Lines Class: HF Induction Brass Solder

Induction Brazing Brass Fitting to Copper Air Lines Class: HF Induction Brass Solder Intro: Objective To braze brass end-connectors to copper tubes used in aircraft assembly air linesMaterial brass end connectors, copper tubes of different diametersTemperature 1400 F 750CFrequency 350 kHzEquipment UM-UHF-6KW induction heating system, including a

Induction Brazing Water Faucets Class: HF Induction Brazing

Induction Brazing Water Faucets Class: HF Induction Brazing Intro: Objective Brazing several brass and copper assemblies used in water faucetsMaterial braze, white fluxTemperature 1350 F 730CFrequency 160 or 277 kHz (coil dependant)Equipment UM-UHF-15kW induction heating system, remote work head with two 1μF capacitors a

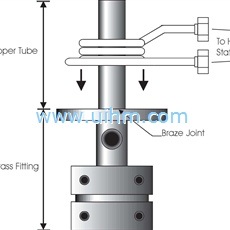

Induction Braze Copper Tube to Brass Fitting Class: HF Induction Brass Solder

Induction Braze Copper Tube to Brass Fitting Class: HF Induction Brass Solder Intro: Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300

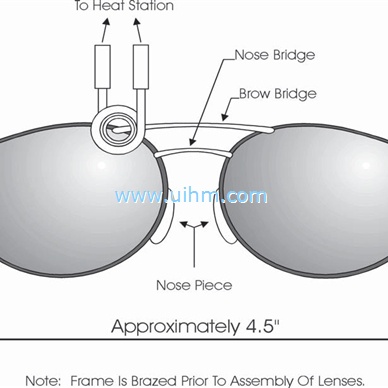

Induction Brazing Eyeglass Frame Assembly Class: HF Induction Brazing

Induction Brazing Eyeglass Frame Assembly Class: HF Induction Brazing Intro: Objective Produce repeatable braze joints for the assembly of eyeglass frames. Induction heating is to be used to achieve quality braze joints on the nose bridge, brow bridge and nose piece.Brazing is to be done at 1300F with approximately 3-5 seconds all

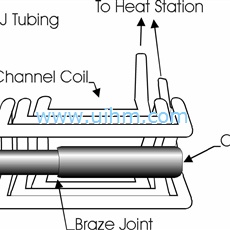

Induction Brazing Copper Tube Class: HF Induction Brazing

Induction Brazing Copper Tube Class: HF Induction Brazing Intro: Objective To braze a copper tube ( 3/8″ OD by 2-4″ long) into a 3/8″fitting in less than 10 seconds. Heating must take place in achannel type coil to allow for easy loading of parts.Material Copper Tubing and Fitting with Braze and Stay Silv White FluxT…

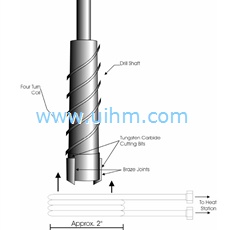

Induction Brazing Carbide Tips on Drill Bits Class: HF Induction Brazing

Induction Brazing Carbide Tips on Drill Bits Class: HF Induction Brazing Intro: Objective To braze carbide cutting tips to drill bits ranging in size from 0.5″ to 1.5″ in diameter. The brazing takes place at 1900F and is presently done in 11 seconds for the 0.5″ diameter bit and 39 seconds for the 1.5″ diameter bit. Customer goals…

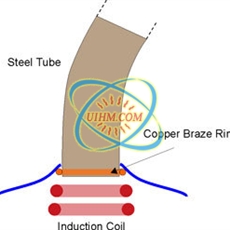

Induction Brazing Steel Tube with Copper Ring Class: HF Induction Brazing

Induction Brazing Steel Tube with Copper Ring Class: HF Induction Brazing Intro: Objective To heat an oil suction assembly (steel tubing and filter cap) to 1,850F (1010C) within 15 seconds for a brazing application.Material 0.125” (3.2mm) diameter steel tube and filter cap assembly, high temperature brazing flux, copper ring.Temperatu

Induction Brazing Turbine Blades Class: HF Induction Brazing

Induction Brazing Turbine Blades Class: HF Induction Brazing Intro: Objective To heat an inconel turbine blade in a vacuum to 2000F and hold temperature for five minutes for a nickel brazing application.Material Inconel turbine blades, nickel metering plates, nickel brazeTemperature 2050FFrequency 20 kHzEquipment ABS Mark

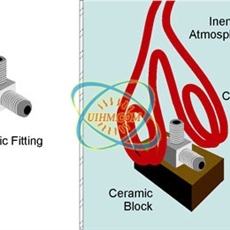

Induction Brazing Steel Fitting Class: HF Induction Brazing

Induction Brazing Steel Fitting Class: HF Induction Brazing Intro: Objective To heat a steel hydraulic hose fitting in an inert atmosphere to 2200F within 7 seconds for brazing without any carbon buildup.Material Three-opening steel hydraulic fitting, pure copper braze pasteTemperature 2200FFrequency 273 kHzEquipment UM-

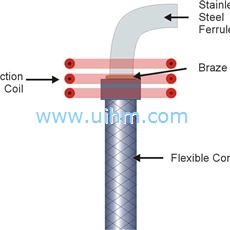

Induction Brazing Steel Conduit Class: HF Induction Brazing

Induction Brazing Steel Conduit Class: HF Induction Brazing Intro: Objective To heat a stainless steel conduit, ferrule and elbow assembly to 1400F (760C) within 20 seconds for brazing.Material 6”(152.4mm)long x 0.5”(12.7mm) diameter stainless steel conduit, 0.5”(12.7mm) long x 0.5”(12.7mm) diameter ferrule, 2”(50.8m…