induction heating inner surface of drum

Views Send Enquiry

Induction heating is often used in the heat treatment of metal

items. The most common applications are induction hardening of steel parts,

induction soldering/brazing as a means of joining metal components and induction

annealing to selectively soften an area of a steel part.

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

induction heating inner surface

Next: induction heating kinfePrevious: induction brass soldering for knife edge

Good

Bad

Related Content

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating bolts from turbine

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

Hot

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

Induction heating for Plastic Reflow With Catheter Tubing

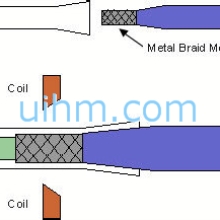

U shape induction coil for heating hole

induction heating steel rod with double coils

Newest Comment

No Comment

Post Comment