what is induction melting

Views Send Enquiry

induction melting

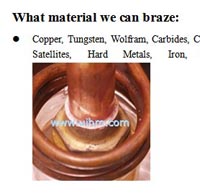

Induction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.

UIHM Induction Melting Furnace provides very efficient & time saving melting of metals for various applications

Features:

- Eco-friendly due to noiseless and flameless operation

- Application Specific

- Auto or manual mode operation

- Improved power factor

- Tropicalised design

- No statutory approvals required

- Lesser risk involved compared to conventional methods

- Compact size

- Uniform metal melting due to induction churning

- Less oxidation loss

- Highest system efficiency

- Highly adaptable for automation

- Easier molten charge handling

- No pre-heating required

- Cost efficient & energy saving

UIHM Induction melting has developed different solutions within a variety of areas such as precious metals, tilting furnace melting, investment casting and lab applications.

With an induction melting furnace the process is considerably cleaner than with a traditional furnace. This means you don't need to purify after the melting, which makes it possible to cut one step in the production process. Lower maintenance costs and machine inventory are some of the benefits.

Induction melting is also safer and more cost-effective. No flame that leads to substantial heat losses or increases the risk of work injuries and fires.

In addition, induction melting is accurate and repeatable—important to secure the quality in your melting processes.

Applications:

- acuum Induction Melting.

- Platinum Melting.

- Very high Temperature Induction Melting.

- Levitation Melting Systems in microgravity of space.

- High Temperature ceramic melting furnace.

- Crystal Growing.

- Alloy Melting.

- Aluminium Foundry.

- Gold Melting.

- Silver Melting.

- Steel Foundry.

induction melting furnace

Good

Bad

Related Content

induction melting 100KG steel by 80KW induction heater with tilting furnace (UM-80AB-MF)

induction melting steel by 100KW induction heater (UM-100AB-MF)

induction melting aluminium

induction melting 5kg gold for casting by 40KW induction heater (UM-40AB-MF)

induction melting 140kg silver with tilting furnace by 100KW induction heater (UM-100AB-MF)

induction melting 150kg silver with tilting furnace by 120KW induction heater (UM-120AB-MF)

induction melting 6kg copper by 80KW induction heater (UM-80AB-MF)

induction melting 150kg copper by 100KW induction heater (UM-100AB-MF) with tilting furnace

Hot

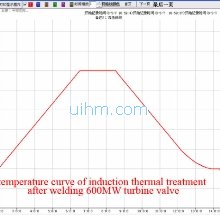

temperature curve of induction thermal treatment after welding 600MW turbine valve

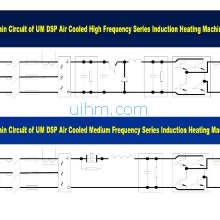

Main Circuit of UM DSP air cooled induction heaters

what is skin effect principle (magnetic force around induction coil)

How to design an optimal induction coil

Applications of induction heating

History of induction heating

what is induction welding

whate is induction tempering or induction preheating

Newest Comment

No Comment

Post Comment