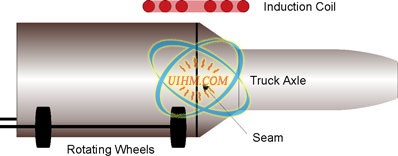

Induction Pre-heating Truck Axle

Views Send Enquiry

Objective To pre-heat the seam of a truck axle to over 300°F within 15 seconds for a welding application and maintain temperature within the welding zone for 15 seconds after the power is

turned off.

Material Steel truck axle; 350° and 400°F temperature indicating paint; 350°, 375°and 400°F temperature indicating “crayons”

Temperature 350°F

Frequency 35 kHz

Equipment Power of 45kW power supply, remote heat station with four 1.2 μF capacitors and a specially designed pancake induction coil.

Process A fixture was constructed to rotate the axle 400° in 15 seconds and the induction coil was placed above the axle. The circumference of the axle (beneath the coil) was painted with 350° and 400°F temperature indicating paint. While the axle was being rotated, RF power was applied for 15 seconds. All of the paint melted, confirming that the axle temperature was above 400°F. The RF power was shut off and the temperature “crayons” were immediately placed against the axle to monitor temperature. The 400°F crayon did not melt; the 375°F crayon melted for 15 seconds; the 350°F crayon melted for 30 seconds.

Results The steel axle was heated to over 400°F within 15 seconds

and temperatures above 350°F were maintained for 30 seconds after power was turned off, meeting the requirements

of the welding application.

Pre-heating Truck Axle

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

install air-cooled clamp coil for preheating pipeline

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction vacuum coating with multi UM-DSP induction heater

induction coating by air cooled clamp induction coil

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine

induction preheating and heat treatment after welding for 600MW turbine

Newest Comment

No Comment

Post Comment