Induction Preheating Titanium Rods

Views Send Enquiry

Objective To heat titanium rod blanks prior to forging into a turbine blade.

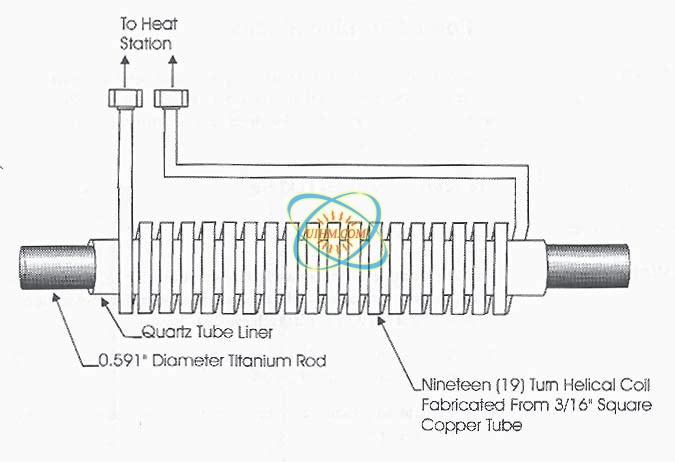

Material Titanium rod blanks 0.591″(15.01mm) OD by 11.8″(299.7mm) long

Temperature 2030ºF(1110°C)

Frequency 64 kHz

Equipment • Power of 45kW induction heating system equipped with a remote workhead comprised of eight (8) capacitors totaling 0.66 μF.

• An induction heating coil designed and developed specifically for this application.

Process A nineteen turn helical coil is used to heat the titanium rod blanks to 2030ºF (1110°C) in 25 seconds.

Results/Benefits Induction heating provides:

• Increased production rates

• Repeatable, reliable & consistent heat without flame.

• Hands free heating that involves no operator skill for manufacturing

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

install air-cooled clamp coil for preheating pipeline

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction vacuum coating with multi UM-DSP induction heater

induction coating by air cooled clamp induction coil

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine

induction preheating and heat treatment after welding for 600MW turbine

Newest Comment

No Comment

Post Comment