Induction Forging Inconel Billets Class: MF Induction Forging

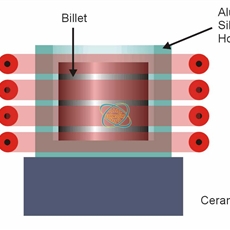

Induction Forging Inconel Billets Class: MF Induction Forging Intro: Forging Inconel Billets Objective To heat inconel billets to 2050F (1121.1C) for a forging process.Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8…

Induction Forge steel rods Class: MF Induction Forging

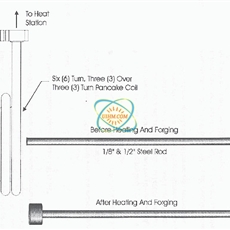

Induction Forge steel rods Class: MF Induction Forging Intro: Objective To heat the ends of steel rods to 1800F prior to a forging operation. Processing of the rods includes heating, pressing in a two part die to forge the push rod end, and a final heating in a channel coil to temper the rods and relieve the forging

Heat Treating Forgings Class: MF Induction Forging

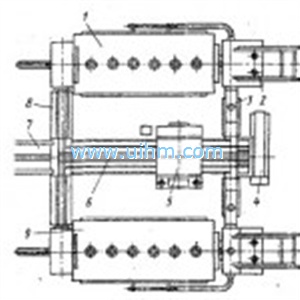

Heat Treating Forgings Class: MF Induction Forging Intro: Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity.The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac 3.

induction foring aluminum bar Class: MF Induction Forging

induction foring aluminum bar Class: MF Induction Forging Intro: As magnetic permeability of aluminum is not good as steel, when aluminum marterial is under induction forging work, it will need a bigger power machine than steel.induction foring aluminum bar

induction forging steel billets Class: MF Induction Forging

induction forging steel billets Class: MF Induction Forging Intro: induction forging steel billets