- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

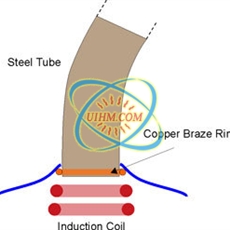

Induction Brazing Steel Tube with Copper Ring

Objective To heat an oil suction assembly (steel tubing and filter cap) to 1,850F (1010C) within 15 seconds for a brazing application.Material 0.125” (3.2mm) diameter steel tube and filter cap assembly, high temperature brazing flux, copper ring.Temperatu

2005/10/02

-

Induction Brazing Turbine Blades

Objective To heat an inconel turbine blade in a vacuum to 2000F and hold temperature for five minutes for a nickel brazing application.Material Inconel turbine blades, nickel metering plates, nickel brazeTemperature 2050FFrequency 20 kHzEquipment ABS Mark

2005/10/02

-

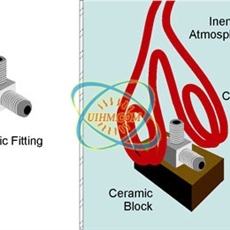

Induction Brazing Steel Fitting

Objective To heat a steel hydraulic hose fitting in an inert atmosphere to 2200F within 7 seconds for brazing without any carbon buildup.Material Three-opening steel hydraulic fitting, pure copper braze pasteTemperature 2200FFrequency 273 kHzEquipment UM-

2005/10/02

-

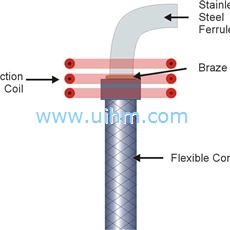

Induction Brazing Steel Conduit

Objective To heat a stainless steel conduit, ferrule and elbow assembly to 1400F (760C) within 20 seconds for brazing.Material 6”(152.4mm)long x 0.5”(12.7mm) diameter stainless steel conduit, 0.5”(12.7mm) long x 0.5”(12.7mm) diameter ferrule, 2”(50.8m…

2005/10/02

-

Mult Induction Brazing Process

Brazing process exudes fumes, emissions and radiations that may be harmful for the people involved in conducting and managing. The people working in this industry are exposed to gases and harmful radiations that are exuded by the brazing of the base metal

2006/03/30

-

Induction Brazing a carbide to a stainless steel shaft

Objective : Brazing a cone shaped carbide to a stainless steel shaft for a diggerMaterial : Cone shaped carbide 1.12” (28.4mm) dia, 1.5”(38.1mm) tall,stainless steel shaft 1.12” (28.4mm) dia and various length, black brazing flux and braze shimsTemperat…

2006/03/30

-

introduction of brazing

What is brazing?The term “brazing” can be applied to any process which joins metals (of the same or dissimilar composition)through the use of heat and a filler metal with a melting temperature above 840 F (450 C), but below the melting point of the meta…

2006/03/30

-

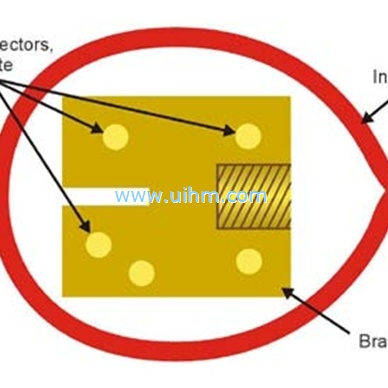

Induction Soldering Steel to Brass

ObjectiveHeat an assembly of small, gold-plated steel connectors to a brass block.Approx. 1/8” (3.2mm) diameter gold-plated steel connectors,1”(25.4mm) square x 1/4” thick brass block ,600F(315.6C),240 kHzTemperature,Frequency,Equipment6 kW induction he…

2006/03/28

-

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

2010/04/30

-

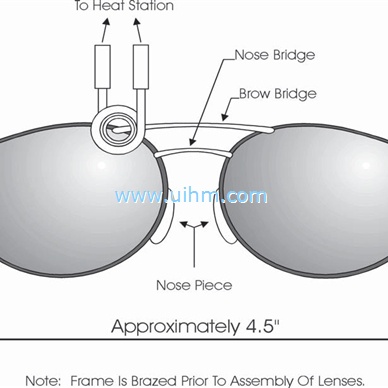

induction brass soldering radiator (heat sink)_2

induction brass soldering radiator (heat sink)_2

2003/08/11

© Copyright 2025. uihm.com All Rights Reserved.