- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

High-frequency induction surface hardening working for the steel

induction hardening HDTV rotating bodies made with the rotation of hardened parts. Long parts hardened inductor in series with the movement along the axis of the member. Cooling the workpiece immediately after the heating is performed by jets of water or

2013/04/08

-

induction Hardening Shaft

Induction hardening is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is

2003/04/01

-

induction hardening for hardware tools

induction hardening for hardware tools

2010/04/30

-

auto induction hardening

auto induction hardening

2009/10/02

-

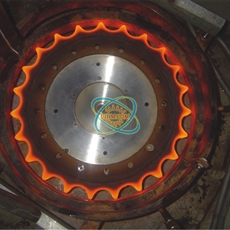

INDUCTION HARDENING OF BEARING PARTS

INDUCTION HARDENING OF BEARING PARTS It is known that induction heating is effective in flow-line mass production that precludesresetting of equipment, or in individual production where the application of ordinaryheating methods is difficult.Induction…

2008/02/03

-

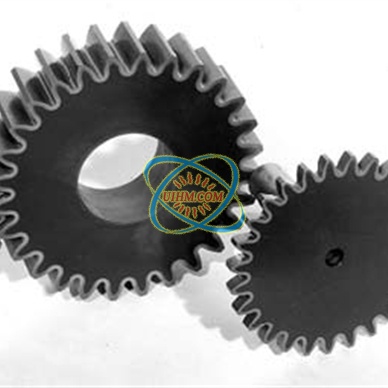

Induction Hardening Teeth Of Gear

Objective Hardening teeth on a steel motorcycle gear to a hardness of 48 – 55 HRCMaterial Carbon steel gear 6.9” (175mm) diameterTemperature 2000 F ( 1093 C)Frequency 78 kHzEquipment •UM-HF-90 kW induction heating system, equipped with a remote workhead…

2007/04/03

-

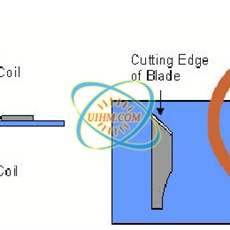

Induction Hardening surgical blades

Objective To quickly heat a steel surgical blade to 2000F (1093C) within 2 seconds so as to harden the blade edge.Material Stainless steel surgical blades, temperature sensing paintTemperature 2000F (1093C)Frequency 339kHzEquipment UM-UHF-6kW induction he

2007/04/03

-

induction Hardening applications

UIHM induction surface hardening applications one application: under torsion and bending load of the alternating workpieces requiring surface layer under the Ministry of higher stress than the heart or abrasion on the surface to be made to strengthen the

2007/04/03

-

Induction hardening belt retraction gear

Objective Heat the teeth of a soft steel seatbelt retraction gear to 1700F (926.7C) within two seconds for hardening.Material #4130 steel seatbelt retraction gears, water vortex quenching tank, electronically controlled air valves, adjustable timersTemper

2007/04/03

-

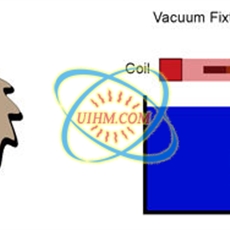

Induction Hardening bed knife blade

Objective Harden a selected area on an 18″(457.2mm) bed knife blade for a reel type lawn mower. The hardness desired is between 45 to 55 Rockwell C, and should be measured 0.062″(1.6mm) from the cutting edge.Material 1070 Steel Bed Knife Blade measuring …

2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.