- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

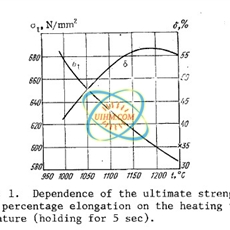

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat…

2008/02/03

-

Steel Induction heat treatment

Overall heat treatment is heating the whole piece, then the appropriate speed cooling, to change its overall mechanical properties of the metal heat treatment process. Roughly the overall heat treatment of steel annealing, normalizing, quenching and tempe

2007/04/03

-

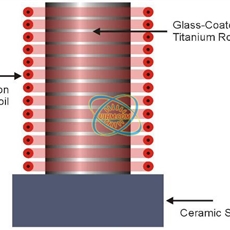

Induction Hot Forming Titanium Rod

Objective To heat a titanium rod to 1700F (926.7C) within 60 seconds for hot forming.Material Titanium rods, 1.25”(31.8mm) diameter, 5”(127mm) lengthTemperature 1700F (926.7C)Frequency 70 kHzEquipment • UM-HF-60kW induction heating system, equipped with…

2007/04/03

-

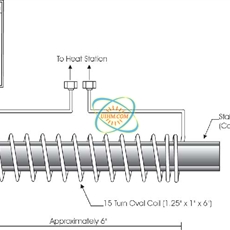

Induction Stainless Steel Hot Forming

Objective: To heat a stainless steel “J” tape to 3000F from room temperature at a rate of 15 feet per minute. The material is to be heated to aid in forming the “J” shape from flat stock.Material: Stainless Steel “J” Tape measuring 0.562″ wide, 0.02…

2007/04/03

-

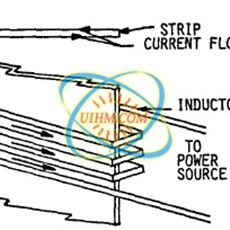

Induction Heat Treating

Induction heating has been used extensively for heat treating processes in a variety of metalworking applications.Some of these applications are associated with discrete parts such as shafts, bearings, gears, and hubs. Here, the most common processes are

2007/04/03

-

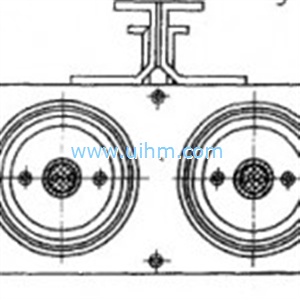

Induction Bending And Hot Rolling

Induction Bending And Hot Rolling the 1620mmX40mm steel pipe in the West-East natural gas transmission project.Induction bending is also referred to as hot rolling, but there are some differences between the two processes. Induction bending is an efficien

2006/03/30

-

Induction Heat Treatment Services

Induction-Heat-Treatment-ServicesShot blasting is creating depressions on the surface of a metal by regularly pelting it with shots of sand or steel balls of a certain diameter. The process is accomplished by employing something like an air gun. A shot bl

2006/03/30

-

Heat Treatment

In recent years this plant is using hardening with preceding induction heating for morethan 50% of the total amount of heat-treated parts. These are mainly tractor parts made from45, 40Kh, 38KhGS, and 33KhS steels. The overwhelming majority of parts (85%

2006/03/28

© Copyright 2025. uihm.com All Rights Reserved.