-

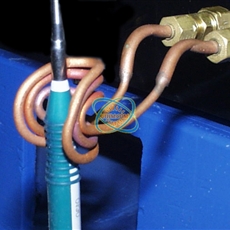

induction heating of the aluminum wire before isolation

Manufacturing of self-bearing insulated cable includes the operation of heating of continuously moving aluminum conductons to temperature 80-120 C prior to application of polyethylene isolation.

2013/04/08

-

Induction Heat Staking: insert metal into plastic

Simultaneous HeatStaking of ThreeSteel InsertsThere are many plastic moldingapplications that require anassembly with two or threeinserts. By simultaneouslyheating the inserts with inductionin a multi-position coil, theinserts can be pushed into thepa…

2013/04/08

-

High Frequency Induction Heating

IntroductionSolid state converters for induction heating are built with different types of switches depending onfrequency range: thyristors for frequencies up to about 10 kHz, IGBTs up to about 100 kHz andPowerMOS up to about 400 kHz. IGBTs have sever…

2013/04/08

-

Induction Brazing Turbine Blades

Process The UIHM ABS Mark 2 with a vacuum level of <510-4 torr was used for the testing. A specially designed induction coil was used to provide optimal heating (approximately 80% energy efficiency) to the braze joint area. The temperature of the j…

2013/04/08

-

What Is Induction Heating

Clean and fast heat being supplied to the heated workpiece meets the considerably increased requirements with regard to environmental protection. The surroundings is not exposedto any thermal and atmospheric pollution. The particular advantage of this…

2013/04/08

-

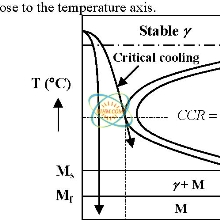

Heat Treatment of Steels

Heat Treating is the process of heating and cooling a steel to obtain desired properties. Various types of heat treatment processes are used to change the following properties or conditions of the steel: - Improve the toughness - Improve the machinabi…

2013/03/28

-

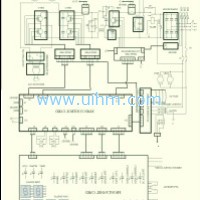

main circuit of UM-25_40_60 RF-HF induction machine

main circuit of UM-25_40_60 RF-HF induction machine

2006/08/03

-

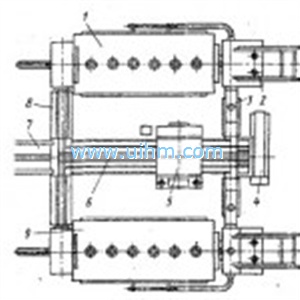

heat-treating-forgings

Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity.The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below …

2006/03/28

-

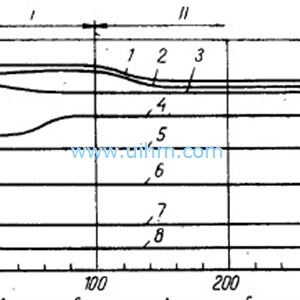

Effect of surface hardening by high frequency induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of th…

2006/03/28

© Copyright 2025. uihm.com All Rights Reserved.