- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Cap Sealing With Induction Heating

Objective An induction heater is used to heat a polymer laminated aluminum foil in 0.5 to 2.0 seconds. The heat produced in the aluminum foil melts the polymer that bonds to the neck of a plastic container.Material Aluminum foil, polyethylene, polypropyle

2007/04/03

-

Induction Sealing Shampoo Container

Objective To heat an aluminum foil inside a plastic shampoo cap for sealingMaterial 2.0” diameter, plastic flip top cap, with a 0.9” diameter aluminum foil sealTemperature 250 – 300 F (120 – 150 C)Frequency 225 kHz Equipment 10 kW, induction heati…

2007/04/03

-

Induction Cap Seal Container

Objective To heat an aluminum in-cap laminate to a temperature of 350F in order to seal the laminate to the containerMaterial 3.5” (100mm)Temperature 350 F (177C)Frequency 300 kHzEquipment UM-UHF-4.5kW induction heating system; custom-designed work coil;

2007/04/03

-

Induction Sealing aluminum foil to plastic bottle

Objective To seal a 1.5” (38.1mm) diameter cap with foil to a plastic bottle.Material 1.5” (38.1mm) diameter cap with 1.5” (38.1mm) diameter aluminum seal, plastic bottleTemperature 250-300 F (121-149 C)Frequency 309 kHz Equipment •UM-UHF-6kW induction …

2007/04/03

-

Induction Curing epoxy

Objective Heat the end of an aluminum copier roller to 400 F (200 C) to cure epoxyMaterial Aluminum roller 4.75” (120mm) diameter, 2’ (0.6m) long with 1.5” (38.1mm) thick plug at endTemperature 400 F (200 C)Frequency 52 kHzEquipment • UM-HF-25 kW induc…

2007/04/03

-

Induction curing coating

Objective Curing a coating on both sides of an aluminum piston at a rate of 1” (25.4mm) per secondMaterial 4 aluminum pistons weighing 1lb (.45kg) each, 3.75” (95.25mm) dia and 2.5” (63.5mm) highTemperature 225 F (107.2 C)Frequency 6 kHzEquipment • UM-…

2007/04/03

-

Induction Curing adhesive

Objective To Cure adhesive in aluminum filter endsMaterial Aluminum filter, steel end caps & plastisol adhesiveTemperature 200 FFrequency 277 kHzEquipment UM-UHF-6kW induction heating system, equipped with a remote workhead containing two 0.1uF capac

2007/04/03

-

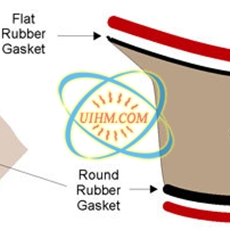

Induction Bonding Rubber to Steel

Objective To bond rubber gaskets to the top and bottom of a steel gas tank assembly.Material Flat and round rubber gaskets, steel gas tank assemblyTemperature 300 to 350F(148.9-176.7C)Frequency 183 kHz for the flat gasket; 231 kHz for the round gasketEqui

2007/04/03

-

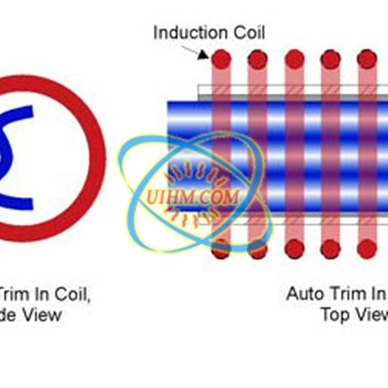

Induction Heating Aluminum Auto Trim

Objective :To heat various sizes of aluminum auto trim to 500F (260C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive.Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tubeTemperature :500 F

2006/03/30

-

Induction Heating Billets

The induction heating of round bars and round-corner-square (RCS) billets are often treated as equivalent applications, even though they are not. This article reconciles recent theoretical and practical achievements in providing required heat uniformity w

2006/03/28

© Copyright 2025. uihm.com All Rights Reserved.