- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Induction Bonding Gasket to Nut

Objective To heat a steel sombrero nut prior to gasket bondingMaterial • Steel sombrero-shaped nut approx. 2” (50.8mm) diameter, 2” (50.8mm) in height • gasketTemperature 350 F (176 C)Frequency 266 kHzEquipment • UM-UHF-6kW induction heating system, e…

2007/04/03

-

Induction Brazing thin walled tube

Objective Braze a NI-SPAN-C alloy tube to a steel cap in a hydrogen atmosphereMaterial NI-SPAN-C alloy tube (5mm) dia, steel cap (7mm) dia, (7mm) long, nickel braze, quartz tube and hydrogenTemperature 1875 F (1024 C)Frequency 313 kHzEquipment • UM-UHF-20

2007/04/03

-

Induction Brazing piston valve

Objective Brazing a steel piston valve assemblyMaterial Steel piston valve 4.5” dia (11.43cm), tungsten carbide plate and brazeTemperature 1350 FFrequency 91 kHzEquipment • UM-HF-90kW induction heating system, equipped with a remote workhead containing s…

2007/04/03

-

Induction Brazing brass faucet

Objective Brazing two joints on a brass bathroom faucet assemblyMaterial Brass bathroom fittings 1” OD, brazing rings, fluxTemperature 1148 F (620 C)Frequency 90 kHzEquipment • UM-HF-90kW induction heating system, equipped with a remote workhead containi…

2007/04/03

-

Induction Brazing manufacture needles

Objective Brazing stainless steel housings to stainless steel tube for gas assembly used in the manufacturing of needlesMaterial 2 stainless steel housings .25” (6.35mm) dia, .675 (17.1mm) & .54” (13.7mm) in length, stainless steel tube .031” (.78mm…

2007/04/03

-

Induction Brazing copper pivot

Objective Brazing a copper pivot assemblyMaterial Two copper uprights 2” (5cm) wide x 4” (10.2cm) high, copper base 3” (7.6cm) x 2” (5cm) and .5” (1.3mm) thick with 2 channels for the uprights to the slide into, braze shims and black fluxTemperature 1…

2007/04/03

-

Induction Brazing heat-sensing probe

Objective To heat a coil and a wire assembly to 1300F (704C) within 60 seconds for brazing.Material Platinum coil, steel wire, braze pasteTemperature 1300F (704C)Frequency 307kHzEquipment UM-UHF-6KW output, remote heat station containing one 1.2 microfara

2007/04/03

-

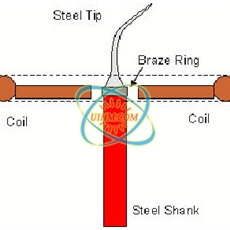

Induction Brazing dental tools

Objective To heat a steel tip and shank assembly to 1300F (704C) within 3 seconds for brazing with induction heating instead of torch brazing.Material 0.1” (2.54mm) diameter steel tip & shank, 0.07” (1.78mm) diameter braze ringTemperature 1300F (704C…

2007/04/03

-

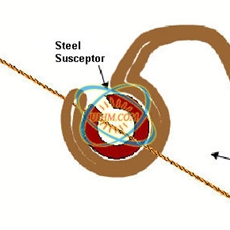

Induction Brazing steel orthodontic parts

Objective To heat a batch of orthodontic parts to 1300F (704C) within 1 second in an inert atmosphere for brazing.Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) cente…

2007/04/03

-

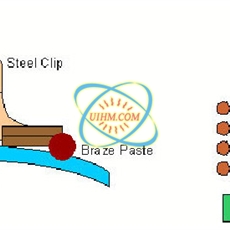

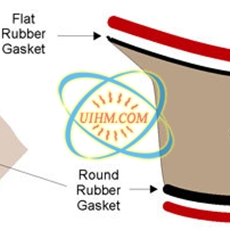

Induction Bonding Rubber to Steel

Objective To bond rubber gaskets to the top and bottom of a steel gas tank assembly.Material Flat and round rubber gaskets, steel gas tank assemblyTemperature 300 to 350F(148.9-176.7C)Frequency 183 kHz for the flat gasket; 231 kHz for the round gasketEqui

2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.