Objective To heat a steel sombrero nut prior to gasket bonding

Material • Steel sombrero-shaped nut approx. 2” (50.8mm) diameter, 2” (50.8mm) in height • gasket

Temperature 350 ºF (176 ºC)

Frequency 266 kHz

Equipment • Power of 6kW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors for a total of 0.75μF

• An induction heating coil, designed and developed specifically for this application.

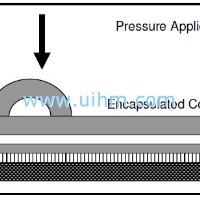

Process A multi-turn pancake coil is used to preheat the nut. It is then transported to the next station where it is pressed onto a gasket for bonding

Results/Benefits Induction heating provides:

• Even distribution of heat that carries through to the bonding station.

• Hands-free operation that involves no operator skill for manufacturing

Material • Steel sombrero-shaped nut approx. 2” (50.8mm) diameter, 2” (50.8mm) in height • gasket

Temperature 350 ºF (176 ºC)

Frequency 266 kHz

Equipment • Power of 6kW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors for a total of 0.75μF

• An induction heating coil, designed and developed specifically for this application.

Process A multi-turn pancake coil is used to preheat the nut. It is then transported to the next station where it is pressed onto a gasket for bonding

Results/Benefits Induction heating provides:

• Even distribution of heat that carries through to the bonding station.

• Hands-free operation that involves no operator skill for manufacturing

Bonding-Gasket-to-Nut

Newest Comment

No Comment

Post Comment