- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Induction Curing Measuring Tape Paint

Objective To heat measuring tape stock at a maximum rate of 600 feet per minute to cure the applied paint. The heating coil is to accommodate the 3/8″ wide stock within the customer’s current framework. Curing must occur above 400F at the rate specified.…

2007/04/03

-

Induction Bonding Solar Panels

Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.Material 3″ by 10.25″ section of a 21″ solar panel shingleTemperature 130 CFr…

2007/04/03

-

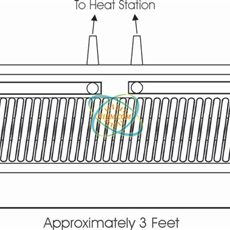

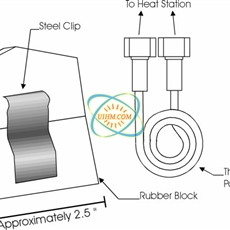

Induction Bonding Steel Clips

Objective To heat metal clips and press-bond them into rubber seals. The metal needs to be heated to 250F to 350F with a cycle time not exceeding 3 secondsMaterial Steel clips and rubber sealer blocksTemperature 250F to 350FFrequency 373 kHzEquipment UM-U

2007/04/03

-

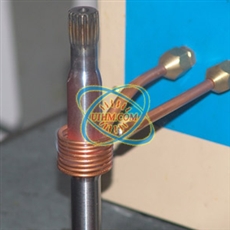

Metal to Plastic by Induction Bonding

Objective To heat a steel magnetic steel post to 300F for a bonding application.Material Magnetic steel posts Plastic handleTemperature indicating paintTemperature 300F (149C)Frequency 288 kHzEquipment UM-UHF-6 kW, 100-400 kHz induction heating power supp

2007/04/03

-

Induction Annealing Stress Relieving

STRESS RELIEVING,NORMALISING AND ANNEALINGStress RelievingStress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling an

2007/04/03

-

INDUCTION HARDENING AND FLAME HARDENING

WHAT ARE THE TREATMENTS?Induction hardening and flame hardening are methods for hardening the surfaces of components, usually in selected areas, by the short-time application of high-intensity heating followed by quenching. The heating and hardening effec

2007/04/03

-

Induction HARDENING AND TEMPERING OF TOOLS

WHAT ARE THE STEELS?Tool and die steels are covered in BS 4659:1989, although both American nomenclature and a variety oftrade names are also in use. Available in high-quality grades, these specifically-designed steels can be groupedbroadly according to t

2007/04/03

-

Induction De-bonding Stainless Steel

Objective To separate bonded stainless steel / carbon fiber assemblies by heating tang, softening the adhesive bondMaterial Stainless steel and carbon fiber insertsTemperature 300 F (149C)Frequency 200 kHzEquipment • UM-UHF-6kW induction heating system, e

2007/04/03

-

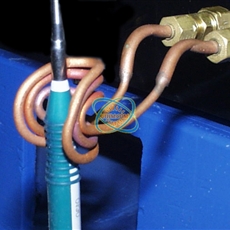

Induction Bonding plastic sleeve to stainless steel handle

Objective Heating end of a stainless steel handle with a plastic sleeve coated with heat adhesive for a bonding applicationMaterial 1” (25mm) OD stainless steel handle 0.30” (7.6) thick covered with a plastic sleeve that is coated with a heat adhesive be…

2007/04/03

-

Induction Debond rubber seal from steel

Objective Debond a fluorocarbon rubber seal from a carbon steel oil seal Material 4” (10.2cm) OD carbon steel oil seal with a fluorocarbon rubber sealTemperature 1200 F (649 C)Frequency 179 kHzEquipment • UM-UHF-6kW induction heating system, equipped wit…

2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.