Objective To separate bonded stainless steel / carbon fiber assemblies by heating tang, softening the adhesive bond

Material Stainless steel and carbon fiber inserts

Temperature 300 ºF (149°C)

Frequency 200 kHz

Equipment • Power of 6kW induction heating system, equipped with a remote workhead containing two 0.33μF capacitors for a total of 0.66 μF).

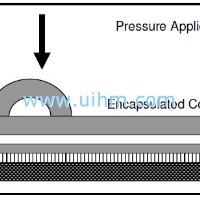

• A helical induction heating coil designed and developed specifically for this application.

Process The bonded part is placed within the helical coil and RF power is applied. Once the metal tang has been warmed, the adhesive bond with the carbon-fiber insert is weakened enough to separate the two sections.

Results/Benefits • process is more environmentally-friendly without the use of noxious chemicals

• process times reduced through direct application of heat

• process efficiency, only the tang is heated

Related

© Copyright 2025. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment