-

Keywords"Hardening",total 166 records

-

induction Hardening pulleys

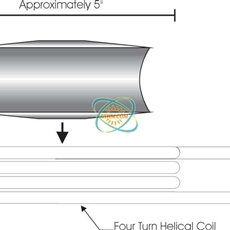

Objective Heat cast iron pulleys to 1600F(871.1C) in order to achieve a hardness of 55 Rockwell C. Material Ductile Iron Pulleys measuring 3 1/2″(88.9mm) OD and 2″ (50.8mm) high. Temperature 1600F (871.1C) Frequency 164 kHz Equipment • Power of 10 k…

Date:2007/04/03

-

induction case Hardening shaft

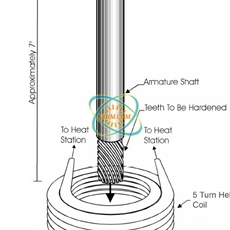

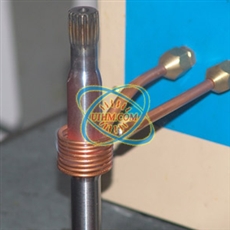

Case hardening shafts Objective Harden the gear end of an armature shaft to 58-65 Rockwell C at a depth of 0.02″(.51mm) on the center line of the teeth and to 49-55 Rockwell C at a depth of .010″ (.3mm) on the center line of the root. Material Ste…

Date:2007/04/03

-

induction Hardening steel cam

Objective To harden the perimeter of ” thick steel cam assemblies Material ” thick steel cam assemblies of varying geometries Temperature 1650 F (900 C) Frequency 177 kHz Equipment Power of 20 kW, induction heating system, equipped with a remote heat…

Date:2007/04/03

-

induction Hardening steel

Objective To harden various size ends of hand held marking stamps. The area to be hardened is 3/4” (19mm) up the shank. Material Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) square Temperature 1550 F (843 C) Frequency 99…

Date:2007/04/03

-

induction Hardening steel screw threads or steel nails

ObjectiveHeat steel roofing screw to 1650 F to harden the threadsMaterial Steel roofing screws of varying diameters less than 1.25” (31.75mm) diameter, 5” (127mm) longTemperature:1650 F (899 C)Frequency:291 kHzEquipment • Power of 6 kW induction heating…

Date:2007/04/03

-

induction Hardening and flame Hardening

WHAT ARE THE TREATMENTS? Induction hardening and flame hardening are methods for hardening the surfaces of components, usually in selected areas, by the short-time application of high-intensity heating followed by quenching. The heating and hardening eff…

Date:2007/04/03

-

induction Hardening and tempering of tools

WHAT ARE THE STEELS?Tool and die steels are covered in BS 4659:1989, although both American nomenclature and a variety oftrade names are also in use. Available in high-quality grades, these specifically-designed steels can be groupedbroadly according to t…

Date:2007/04/03

-

effect of surface Hardening by induction heating

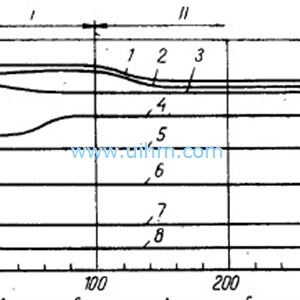

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the spe…

Date:2006/03/28

-

induction surface Hardening

Kelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: An Analytical Approach including Magnetic Losses Abstract– Kelvin effect(Skin effect) is used in surface hardening produced by induction heating of gears, cam forms, camsh…

Date:2006/03/28

-

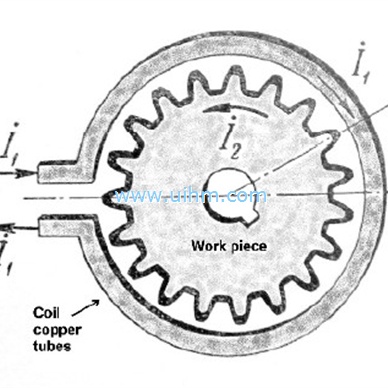

induction Hardening gears

In recent years, gear manufacturers have gained additional knowledge about how technology can be used to produce quality parts. The application of this knowledge has resulted in gears that are quieter, lighter, and lower cost, and have an increased load-ca…

Date:2004/06/27

© Copyright 2025. uihm.com All Rights Reserved.