-

Keywords"n",total 3020 records

-

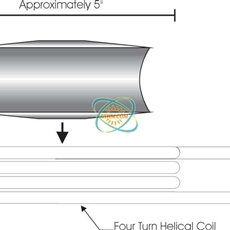

induction hardening bed knife blade

Objective Harden a selected area on an 18″(457.2mm) bed knife blade for a reel type lawn mower. The hardness desired is between 45 to 55 Rockwell C, and should be measured 0.062″(1.6mm) from the cutting edge. Material 1070 Steel Bed Knife Blade measurin…

Date:2007/04/03

-

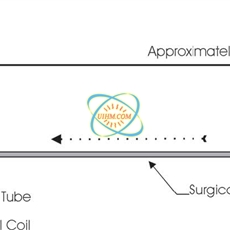

induction hardening surgical knife blades

Objective Harden a 4″(101.6mm) section of a Stainless Steel surgical blade measuring 7″ (177.8mm) long. Hardness should be 48 to 53 Rockwell C on the blade after processing. Material 420 Stainless Steel Surgical Blades measuring 7″(177.8mm) long, 1/4″…

Date:2007/04/03

-

induction hardening pulleys

Objective Heat cast iron pulleys to 1600F(871.1C) in order to achieve a hardness of 55 Rockwell C. Material Ductile Iron Pulleys measuring 3 1/2″(88.9mm) OD and 2″ (50.8mm) high. Temperature 1600F (871.1C) Frequency 164 kHz Equipment • Power of 10 k…

Date:2007/04/03

-

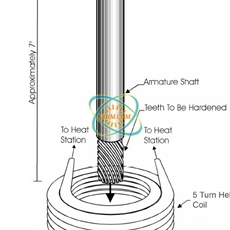

induction case hardening shaft

Case hardening shafts Objective Harden the gear end of an armature shaft to 58-65 Rockwell C at a depth of 0.02″(.51mm) on the center line of the teeth and to 49-55 Rockwell C at a depth of .010″ (.3mm) on the center line of the root. Material Ste…

Date:2007/04/03

-

induction hardening steel cam

Objective To harden the perimeter of ” thick steel cam assemblies Material ” thick steel cam assemblies of varying geometries Temperature 1650 F (900 C) Frequency 177 kHz Equipment Power of 20 kW, induction heating system, equipped with a remote heat…

Date:2007/04/03

-

induction hardening steel

Objective To harden various size ends of hand held marking stamps. The area to be hardened is 3/4” (19mm) up the shank. Material Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) square Temperature 1550 F (843 C) Frequency 99…

Date:2007/04/03

-

induction hardening steel screw threads or steel nails

ObjectiveHeat steel roofing screw to 1650 F to harden the threadsMaterial Steel roofing screws of varying diameters less than 1.25” (31.75mm) diameter, 5” (127mm) longTemperature:1650 F (899 C)Frequency:291 kHzEquipment • Power of 6 kW induction heating…

Date:2007/04/03

-

cap sealing with induction heating

Objective An induction heater is used to heat a polymer laminated aluminum foil in 0.5 to 2.0 seconds. The heat produced in the aluminum foil melts the polymer that bonds to the neck of a plastic container.Material Aluminum foil, polyethylene, polypropylen…

Date:2007/04/03

-

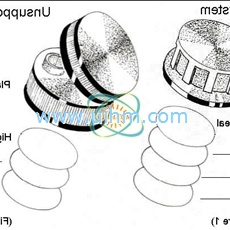

induction sealing shampoo container

Objective To heat an aluminum foil inside a plastic shampoo cap for sealingMaterial 2.0” diameter, plastic flip top cap, with a 0.9” diameter aluminum foil sealTemperature 250 – 300 F (120 – 150 C)Frequency 225 kHzEquipment Power of 10 kW, induction he…

Date:2007/04/03

-

induction cap seal container

Objective To heat an aluminum in-cap laminate to a temperature of 350F in order to seal the laminate to the container Material 3.5” (100mm) Temperature 350 F (177C) Frequency 300 kHz Equipment Power of 4.5kW induction heating system; custom-designed w…

Date:2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.