Induction Shrink fit steel ring

Views Send Enquiry

Objective Heating a steel band to 1000 ºF (538 ºC) and inserting a carbon graphite ring in the center of the steel band

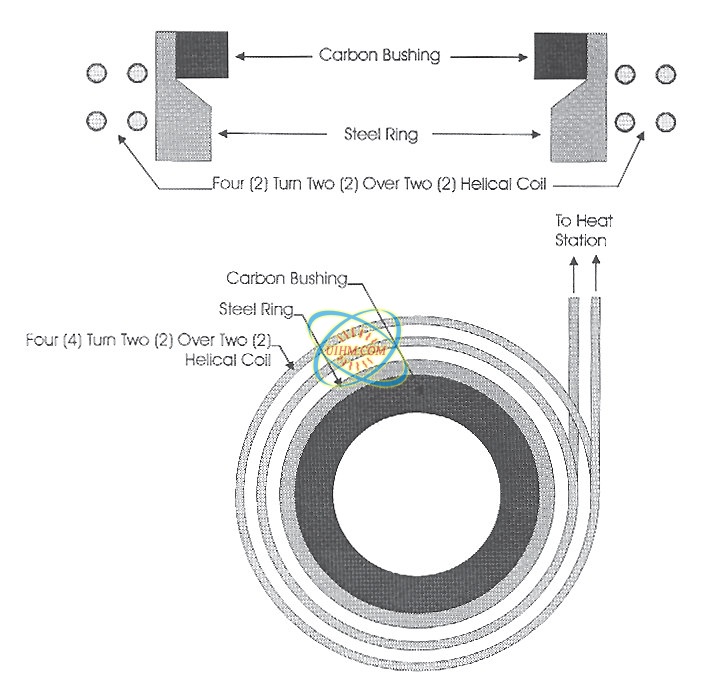

Material 4340 steel ring 8” (20.3cm) OD x 7.75” (19.7cm) ID, .895” (22.7mm) thick, carbon graphite ring insert

Temperature 1000 ºF (538 ºC)

Frequency 32 kHz

Equipment • Power of 45 kW induction heating system, equipped with a remote workhead containing eight capacitors.

• An induction heating coil designed and developed specifically for this application.

Process A four turn, two over two helical coil is used for heating the steel ring. Power is applied for 14 seconds to reach the 1000ºF (538 ºC), the carbon graphite ring is inserted and the assembly is allowed to cool creating a strong joint between the two pieces.

Results/Benefits Induction heating provides:

• A highly effective joint

• Accurate & repeatable heat

• Precise control of cycle times

• Uniform and repeatable results

• Hands-free heating that involves no operator skill for manufacturing

Shrink fit steel ring

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction shrink fitting motor (stator or rotor)

induction installation (shrink fitting) couplings for Shaft Collar with flexible induction coil

induction shrink fitting wheel

induction shrink fitting stator

induction shrink fitting spindle

induction shrink fitting for rotor and stator

air cooled induction heating for fixing Nuclear Power Unit (loosen screw nut)

induction shrink fitting

Newest Comment

No Comment

Post Comment