Induction Levitation melting steel balls

Views Send Enquiry

Objective Levitation of steel balls during the melting process

Material 1010 low carbon steel balls ¼” (6.35mm) diameter

Temperature 2800 ºF (1538 ºC)

Frequency 195 kHz

Equipment • Power of 30 kW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors for a total of 0.75μF

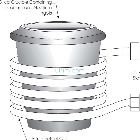

• An induction heating coil designed and developed specifically for this application.

Process A conical coil is used with a total of five turns with two turns on the bottom, a central turn and two turns wound the opposite direction on the top, this creates opposing fields that causes the steel ball to levitate. The ball is introduced into the coil on a quartz rod. When the power is turned on the metal is heated and the opposing magnetic fields levitate the metal ball inside

the coil. The metal continues to heat until it melts.

Results/Benefits Induction heating provides:

• Minimal contamination of conductive material during manufacturing

• Removes insoluble inclusions while leaving desired alloying constituents in tact

• Even distribution of heating

Levitation melting steel balls

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment