Induction Curing Measuring Tape Paint

Views Send Enquiry

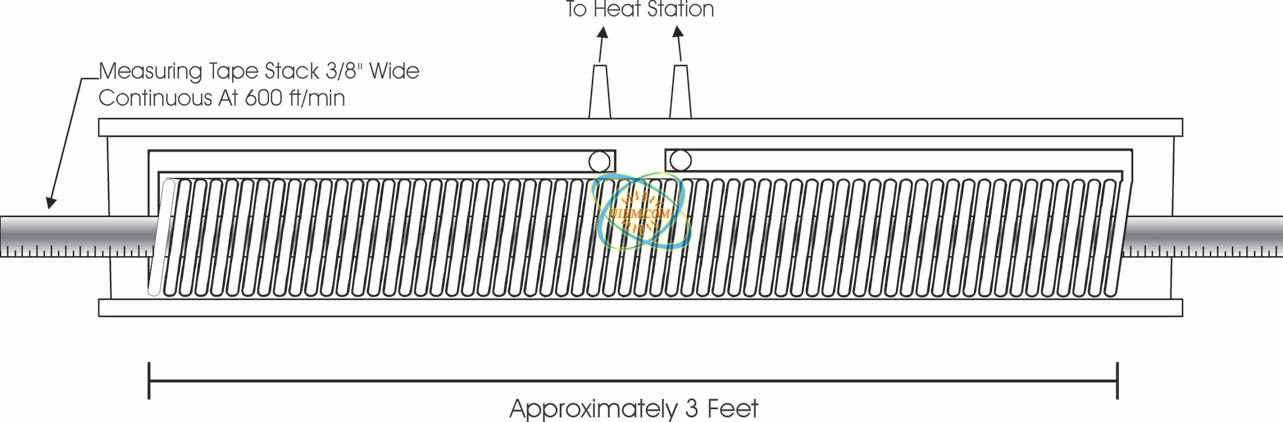

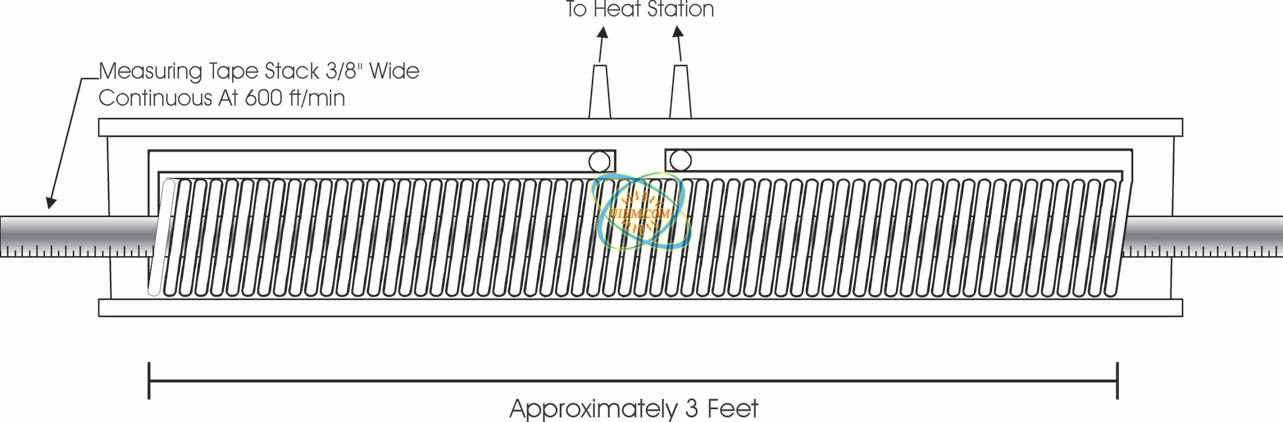

Objective To heat measuring tape stock at a maximum rate of 600 feet per minute to cure the applied paint. The heating coil is to accommodate the 3/8″ wide stock within the customer’s current framework. Curing must occur above 400°F at the rate specified.

Material Steel Measuring Tape stock, 3/8″ wide on a continuous feed.

Temperature Above 400°F

Frequency 75 kHz

Equipment Power of 45kW output solid state induction power supply with remote heat station housing eight (8) 0.33 μF capacitors totaling 0.66 μF, along with a 30″ multi turn helical coil designed specifically for this application.

Process The UIHM 20kW output solid state induction power supply along with a unique 30″ long multi turn helical coil was found to produce the following results.

Results • A temperature of 500°F was achieved, at the necessary rate, using the unique 30″ multi-turn helical coil which surpasses the customer’s requirement of 400°F.

• The helical coil was designed to integrate with the customer’s present framework to eliminate any re-fixturing.

• The helical coil allows for the tape to travel internally with absolutely no contact thus maximizing surface quality.

Material Steel Measuring Tape stock, 3/8″ wide on a continuous feed.

Temperature Above 400°F

Frequency 75 kHz

Equipment Power of 45kW output solid state induction power supply with remote heat station housing eight (8) 0.33 μF capacitors totaling 0.66 μF, along with a 30″ multi turn helical coil designed specifically for this application.

Process The UIHM 20kW output solid state induction power supply along with a unique 30″ long multi turn helical coil was found to produce the following results.

Results • A temperature of 500°F was achieved, at the necessary rate, using the unique 30″ multi-turn helical coil which surpasses the customer’s requirement of 400°F.

• The helical coil was designed to integrate with the customer’s present framework to eliminate any re-fixturing.

• The helical coil allows for the tape to travel internally with absolutely no contact thus maximizing surface quality.

Next: Induction Curing Ceramic FiberPrevious: Induction Bonding Solar Panels

Good

Bad

Hot

install air-cooled clamp coil for preheating pipeline

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction vacuum coating with multi UM-DSP induction heater

induction coating by air cooled clamp induction coil

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine

induction preheating and heat treatment after welding for 600MW turbine

Newest Comment

No Comment

Post Comment