Induction Heating carbon graphite anodes Class: Other Induction Applications

Induction Heating carbon graphite anodes Class: Other Induction Applications Intro: Heating carbon graphite anodes Objective Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminantsMaterial anodes 2.5 x 2.5 x 4 (63 x 63 x 102) h x w x d in (mm)Temperature 1900 F 1000CFrequency 54 kHzEquipment…

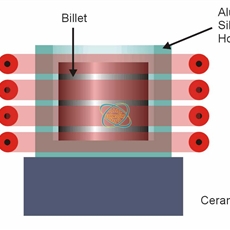

Induction Forging Inconel Billets Class: MF Induction Forging

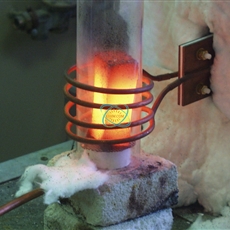

Induction Forging Inconel Billets Class: MF Induction Forging Intro: Forging Inconel Billets Objective To heat inconel billets to 2050F (1121.1C) for a forging process.Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8…

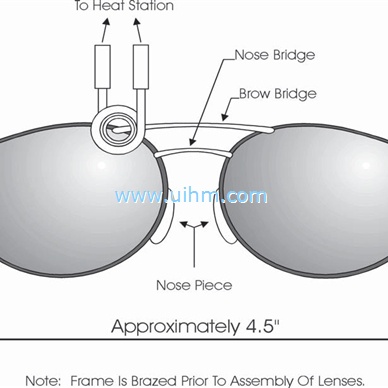

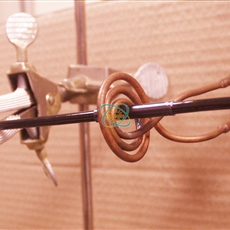

Induction Silver Soldering Class: Induction Soldering

Induction Silver Soldering Class: Induction Soldering Intro: Silver Soldering Soldering is the process in which two or more metal items are fused or joined together usually using flux & solder with heat as a catalyst. To solder silver findings to jewellery, such as a catch or pendant to a chain, certain pro…

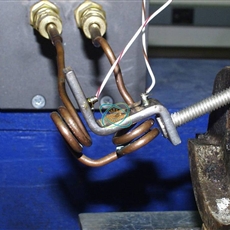

Induction Soldering copper wires Class: Induction Soldering

Induction Soldering copper wires Class: Induction Soldering Intro: Soldering copper wires Objective Soldering two copper wires to pre-installed turrets on a copper buss barMaterial Solder dipped copper/nickel buss bar, 2 tinned stranded copper wires, brazing stickTemperature 446 F (230 C)Frequency 230 kHzEquipment •…

Induction silver brazing with induction heating Class: HF Induction Brazing

Induction silver brazing with induction heating Class: HF Induction Brazing Intro: silver brazing with induction heatingInduction Silver brazing actually uses not pure silver, but instead a silver alloy containing nonferrous metal to bond two pieces of metal together. The process is typically used to join close-fitting parts that re…

Induction Silver soldering with induction heating Class: Induction Soldering

Induction Silver soldering with induction heating Class: Induction Soldering Intro: Silver soldering with induction heating A full treatise on silver soldering (otherwise known as hard soldering) would be an extensive document, and all I want to cover here is the basics. A serious job such as constructing a model locomotive boiler re…

Induction Melting Gold and Silver Class: Rare Metals Melting

Induction Melting Gold and Silver Class: Rare Metals Melting Intro: Melting Gold and Silver Everything for Gold and Silver Melting, it used to be that when melting gold, people used a blow torch, then a torch, then an electric melter and then an induction melter. Whatever your choice, we have the torch, the electric m…

Induction Bin Brazing Class: HF Induction Brazing

Induction Bin Brazing Class: HF Induction Brazing Intro: Bin Brazing Pin Brazing forms part of a technology developed in Sweden throughout the latter half of the 20th century by AGA. The purpose, for attaching current carrying cables to what were deemed Sensitive Substrate Materials, or in this case Railroa…

Induction Fusing the butt joint Class: Induction Jointing

Induction Fusing the butt joint Class: Induction Jointing Intro: Fusing the butt joint Objective Fuse elastomer (TPE) tubes together in two ways, as a butt joint and as a overlap joint.Material PeBax tubing 3/16” (4.76) OD, 1/8” (3.18 mm) ID and slightly largerStainless steel Teflon coated mandrel 1/8” (3.18 mm)…

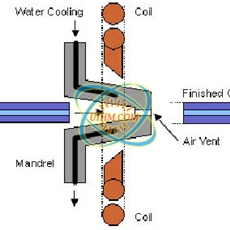

Induction Heating brass mandrel die Class: HF Induction Brass Solder

Induction Heating brass mandrel die Class: HF Induction Brass Solder Intro: Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller.Material materials, supplies involved in the applicationTemperature 400F (204C)Frequency 325kHzEquipment Power …

Recommended

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction brazing diamond segment

induction melting for crystal growth

induction unassemble 2Ton guard ring of turbine

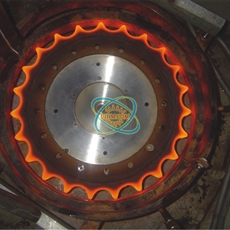

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine