Crucible melting various materials in nitrogen atmosphere

Views Send Enquiry

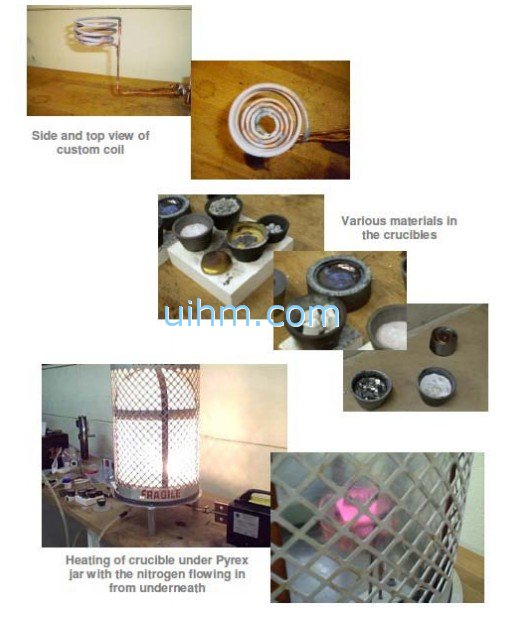

Objective Heat to melting point various materials in a nitrogen atmosphere in a graphite or molybdenum crucible.

Material Magnesium fluoride, tantalum pentoxide, aluminum, yttrium fluoride, germanium, hafnium or titanium dioxide and a Pyrex bell jar

Temperature Melting temperatures varies

Frequency 60 kHz

Equipment

• 45 kW induction heating system, equipped with a remote head machine containing two 1.0μF capacitors for a total of 0.5 μF

• 45 kW induction heating system, equipped with a remote head machine containing two 1.0μF capacitors for a total of 0.5 μF

• An induction heating coil designed and developed specifically for this application.

Process The crucible is heated using a coil with a four turn pancake at the base that extends upward into a three turn helical coil.

Times and melting temperatures vary due to the properties of the different materials.

Results/Benefits Induction heating provides:

• Faster process time than electron beam heating.

• Repeatable, consistent results.

Even distribution of heating.

Crucible melting various materials in nitrogen atmosphere

PDF: Crucible melting various materials in nitrogen atmosphere

Good

Bad

Related Content

Hot

induction melting metal sand after air cooled preheating

induction melting with Titanium alloy pot by customized induction coil

magnesium oxide acidic furnace for induction melting glass

induction melting steel

induction melting silver

induction melting silicon and steel

induction melting aluminium for casting wire wheel

induction melting copper billets

Newest Comment

No Comment

Post Comment