Induction quenching is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction quenching is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole.

Induction quenching is one of Induction heating's main application areas. Thousands of our quenching solutions are at work around the world—many of them within the automotive industry.

Process

Induction heating is a non contact heating process which utilises the principle of electromagnetic induction to produce heat inside the surface layer of a work-piece. By placing a conductive material into a strong alternating magnetic field, electrical current can be made to flow in the material thereby creating heat due to the I2R losses in the material. In magnetic materials, further heat is generated below the curie point due to hysteresis losses. The current generated flows predominantly in the surface layer, the depth of this layer being dictated by the frequency of the alternating field, the surface power density, the permeability of the material, the heat time and the diameter of the bar or material thickness. By quenching this heated layer in water, oil or a polymer based quench the surface layer is altered to form a martensitic structure which is harder than the base metal.

Definition

A widely used process for the surface quenching of steel. The components are heated by means of an alternating magnetic field to a temperature within or above the transformation range followed by immediate quenching. The core of the component remains unaffected by the treatment and its physical properties are those of the bar from which it was machined, whilst the hardness of the case can be within the range 37/58 HRC. Carbon and alloy steels with an equivalent carbon content in the range 0.40/0.45% are most suitable for this process.

A source of high frequency electricity is used to drive a large alternating current through a coil. The passage of current through this coil generates a very intense and rapidly changing magnetic field in the space within the work coil. The workpiece to be heated is placed within this intense alternating magnetic field where eddy currents are generated within the workpiece and resistance leads to Joule heating of the metal.

This operation is most commonly used in steel alloys. Many mechanical parts, such as shafts, gears, and springs, are subjected to surface treatments, before the delivering, in order to improve wear behavior. The effectiveness of these treatments depends both on surface materials properties modification and on the introduction of residual stress. Among these treatments, induction quenching is one of the most widely employed to improve component durability. It determines in the work-piece a tough core with tensile residual stresses and a hard surface layer with compressive stress, which have proved to be very effective in extending the component fatigue life and wear resistance.

Induction surface hardened low alloyed medium carbon steels are widely used for critical automotive and machine applications which require high wear resistance. Wear resistance behavior of induction hardened parts depends on quenching depth and the magnitude and distribution of residual compressive stress in the surface layer.

The main benefit of induction heating for quenching is that it takes just a few seconds. In a furnace, the same process can take hours or even days. Why is that possible?

The answer is that induction is phenomenal at generating heat fast. This, in turn, means you can integrate quenching in the production process. quenching in a furnace, on the other hand, is more time-consuming (greater heat loss) and requires moving the components either to your own furnace or to that of a sub-contractor.

In-line integration of quenching reduces your lead times considerably. You get full control over quality, delivery times and costs. There's no need to transport kilos of components back and forward, which saves energy and the environment. And last but not least, you cut down the amount of administration to a minimum.

induction quenching steel pipe

induction quenching gear

induction quenching TCT (tungsten carbide tool) parts

induction quenching surface of engine part to 0.1mm depth by 300KW UHF induction heaters

induction quenching steel rods

induction quenching large steep pipe by 500KW RF induction heater (2)

induction quenching large steep pipe by 500KW RF induction heater (1)

induction quenching lager steel shaft by SCR induction heater

induction quenching knives by HF induction heaters

induction quenching incision of steel pipe

induction quenching gear tooth

induction quenching gear teeth by 200KW induction heater

induction quenching cylinder stator surface

induction quenching brake flange by 200KW UHF induction heater

induction quenching banana knife edge (sickle blade)

induction quenching brake disk of automobile by UHF induction heater

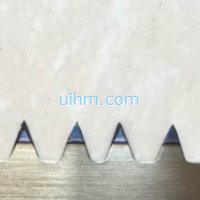

induction quenching bandsaw teeth by UHF induction heater

induction quenching axles by dual induction coils

induction quenching steel pipe Type:

induction quenching steel pipe Type:

Class: HF Induction QuenchingIntro: induction quenching steel pipe

induction quenching gear Type:

induction quenching gear Type:

Class: HF Induction QuenchingIntro: induction quenching gear

induction quenching TCT (tungsten carbide tool) parts Type:

Class: HF Induction QuenchingIntro: induction quenching TCT (tungsten carbide tool) parts (1)induction quenching TCT (tungsten carbide tool) parts (3)induction quenching TCT (tungsten carbide tool) parts (2)induction quenching TCT (tungsten carbide tool) parts (4)

Recommended

Gear shaft induction hardening

induction quenching surface metal with magnetic core

induction quenching surface metal with magnetic core 2

induction quenching surface metal with magnetic core 1

induction quenching with special out-of-shape coil

induction quenching axle

induction quenching axle edge

induction quenching axle 1