UIHM offers a full range of solid-state induction welding machines fitted with induction coils or/and contact heads.

Our Induction welding solutions are primarily found in the tube and pipe industry.

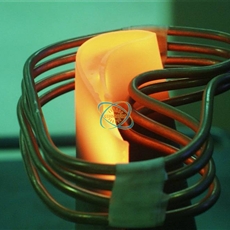

Induction welding is a form of welding that uses electromagnetic induction to heat the workpiece.

The welding apparatus contains an induction coil that is energised with a radio-frequency electric current.

This generates a high-frequency electromagnetic field that acts on either an electrically conductive or a ferromagnetic workpiece. In an electrically conductive workpiece, the main heating effect is resistive heating, which is due to induced currents called eddy currents. In a ferromagnetic workpiece, the heating is caused mainly by hysteresis, as the electromagnetic field repeatedly distorts the magnetic domains of the ferromagnetic material. In practice, most materials undergo a combination of these two effects.

Nonmagnetic materials and electrical insulators such as plastics can be induction-welded by implanting them with metallic or ferromagnetic compounds, called susceptors, that absorb the electromagnetic energy from the induction coil, become hot, and lose their heat to the surrounding material by thermal conduction.

Induction welding is used for long production runs and is a highly automated process, usually used for welding the seams of pipes. It can be a very fast process, as a lot of power can be transferred to a localised area, so the faying surfaces melt very quickly and can be pressed together to form a continuous rolling weld.

The depth that the current, and therefore heating, penetrates from the surface is inversely proportional to the square root of the frequency. The temperature of the metals being welded and their composition will also affect the penetration depth. This process is very similar to resistance welding, except that in the case of resistance welding the current is delivered using contacts to the workpiece instead of using induction.

All of our UM induction welding machines have rugged, independent full-bridge IGBT transistors. These transistors are virtually short-circuit proof, considerably boosting reliability and uptime.

You also get more output capacity to our continuous electronic load matching. This secures full power output across a wide range of tube sizes (OD 3/8”-26”/10mm-600 mm), ensuring maximum welding speed for each size.

Moreover, you can reduce your power consumption. The efficiency from input at the rectifier to output at the coil is, at least 85-87 percent. And the use of diode rectifiers results in a high, constant power factor (0.85) at all power levels—thereby eliminating the need for costly reactive power compensation capacitors.

high frequency induction welding (HFIW) continuous butt welding of tubes

induction welding automotive stainless plate for Toyato

induction welding drill bit (bore bit or drill pipe or drill rod or cutting pick)

induction welding steel bar

induction welding phosphor copper rings

induction tin soldering distributor branches

induction Welding for stainless stell workpiece

Induction Welding for HDMI and USB

induction welding of diamond teeth

Induction Heating fan blades for welding

induction welding motor short-curcuit ring by flexible handle induction coil

induction welding motor (generator windings) short-curcuit ring

high frequency induction welding (HFIW) continuous butt welding of tubes Type:

high frequency induction welding (HFIW) continuous butt welding of tubes Type:

Class: Induction WeldingIntro: high frequency induction welding (HFIW) continuous butt welding of tubes

induction welding automotive stainless plate for Toyato Type:

induction welding automotive stainless plate for Toyato Type:

Class: Induction WeldingIntro:

induction welding drill bit (bore bit or drill pipe or drill rod or cutting pick) Type:

induction welding drill bit (bore bit or drill pipe or drill rod or cutting pick) Type:

Class: Induction WeldingIntro: induction welding drill bit (bore bit or drill pipe or drill rod or cutting pick)