High frequency induction brazing pipes for copper and iron alloys

Views Send Enquiry

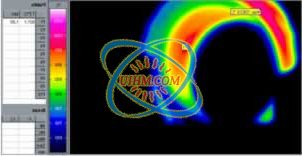

High frequency induction brazing is an energy-saving technology. High specific power, which are implemented by induction heating to quickly heat the local area to the brazing temperature 600 - 1200 ° C, spending at the lowest energy in the process compared to conventional gas heating methods.

Stainless steel pipes are joined by brazing induction brazing HDTV in the manufacture of towel radiators and pipes for various purposes.

Pipes and flanges are made ??of copper, brass and other copper alloys are used mainly in the manufacture of cooling systems of various process units.

|

|

|

|

In addition to excessive energy consumption during slow heating of the gas soldering quality is deteriorating due to lower efficiency of flux, heat the adjacent parts, reduced productivity.

Plants for soldering consist of a transistor oscillator TGI capacity of 12, 25 or 40 kW heating unit with an inductor and a snap.

The application of high frequency induction brazing:

windings of electrical machines and transformers, carbide inserts cutting tools, tips rippers, piping, heated towel rails, flanges and end pipes, etc.

PDF: High frequency induction brazing pipes for copper and iron alloys

Related Content

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment