Induction Annealing Brazing Wire

Views Send Enquiry

Objective: Anneal a brazing wire for preform production.

Material :Copper Nickel Silver 2774 Alloy rod 0.070″ (1.8mm) diameter.

Temperature 650ºF(343.3ºC)

Frequency 281 kHz

Equipment • UM-06A-UHF induction heating system equipped with a remote workhead with one 1.0 μF capacitor, and a 4-20mA input controller to aid in voltage ramping.

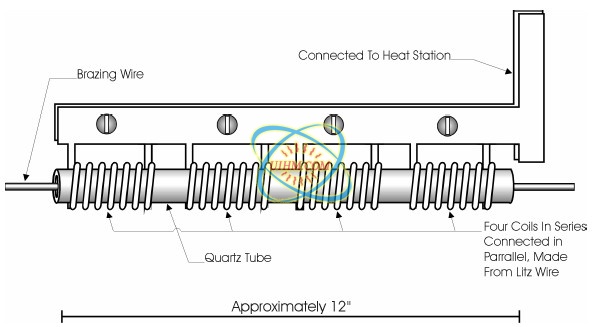

• An induction heating coil designed and developed specifically for this application.

Process A unique helical coil consisting of four consecutive coils connected in parallel with a quartz tube lining is used to heat the wire to 650ºF (343.3ºC) for annealing.

Results/Benefits Induction heating provides:

• Higher productivity of 27’ (8.2m) per minute

• Reduction in surface oxidation & scaling

• Consistent, repeatable results

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater

induction annealing SS-Steel knife

induction annealing copper plate

induction heating steel pipe by flexible water cooled induction coil

induction annealing with U shape double ear induction coil

induction annealing steel strip online

induction annealing with large parallel induction coil

induction annealing steel plate by U shape double ear induction coil

Newest Comment

No Comment

Post Comment