Induction Annealing Stainless Steel

Views Send Enquiry

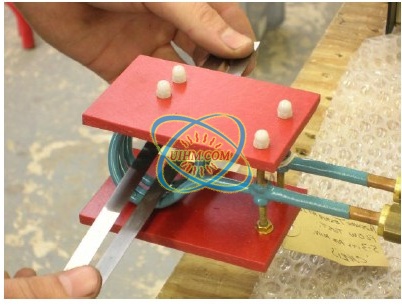

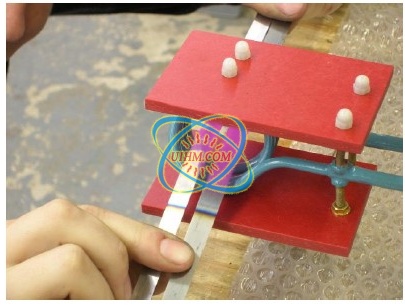

Induction Annealing stainless steel bread cutting saw blades

Objective: Anneal saw blades used for cutting bread, prior to hole punching.

Material :.38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel.

Temperature :600°C (315.6°F) for one second

Induction Annealing Process :A three turn helical coil at a 45º angle is used to anneal a 1.2”(30.5mm) strip of saw blade prior to hole punching.

Results/Benefits :Induction heating provides:

• Improved quality of blades at hole punching location

• Decreased scrap product

• Easily incorporated into existing production lines

Next: Induction Soldering Steel to BrassPrevious: Induction Shrink Fitting

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater

induction annealing SS-Steel knife

induction annealing copper plate

induction heating steel pipe by flexible water cooled induction coil

induction annealing with U shape double ear induction coil

induction annealing steel strip online

induction annealing with large parallel induction coil

induction annealing steel plate by U shape double ear induction coil

Newest Comment

No Comment

Post Comment