Induction Brazing Copper Tube

Views Send Enquiry

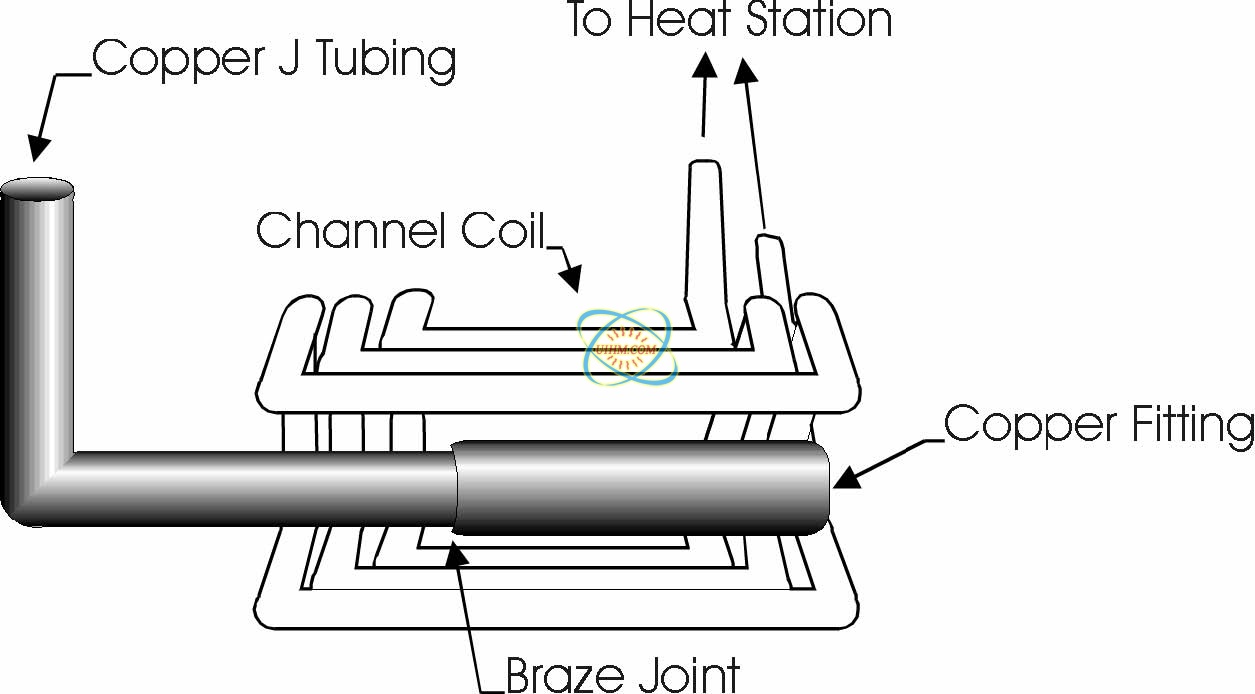

Objective To braze a copper tube ( 3/8″ OD by 2-4″ long) into a 3/8″

fitting in less than 10 seconds. Heating must take place in a

channel type coil to allow for easy loading of parts.

Material Copper Tubing and Fitting with Braze and Stay Silv White Flux

Temperature 1300°F

Frequency 105 kHz

Equipment Power of 10 kW output solid state induction power supply equipped with a standard heat station containing eight 0.33 μF capacitors for a total of 0.66μF, a step down transformer, and a specifically designed induction heating coil.

Process Power of 10 kW solid state induction power supply was setup to achieve the following results:

· 2.0 kW of power was directly loaded into the copper tube resulting in a heating time of 7.2 seconds to reach the

necessary 13000F for brazing.

Results Processing ease was achieved through the design of a unique channel type coil comprised of three turns of 1/8″ copper

fitting in less than 10 seconds. Heating must take place in a

channel type coil to allow for easy loading of parts.

Material Copper Tubing and Fitting with Braze and Stay Silv White Flux

Temperature 1300°F

Frequency 105 kHz

Equipment Power of 10 kW output solid state induction power supply equipped with a standard heat station containing eight 0.33 μF capacitors for a total of 0.66μF, a step down transformer, and a specifically designed induction heating coil.

Process Power of 10 kW solid state induction power supply was setup to achieve the following results:

· 2.0 kW of power was directly loaded into the copper tube resulting in a heating time of 7.2 seconds to reach the

necessary 13000F for brazing.

Results Processing ease was achieved through the design of a unique channel type coil comprised of three turns of 1/8″ copper

brazing-coppeer

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment