Induction Brazing dental tools

Views Send Enquiry

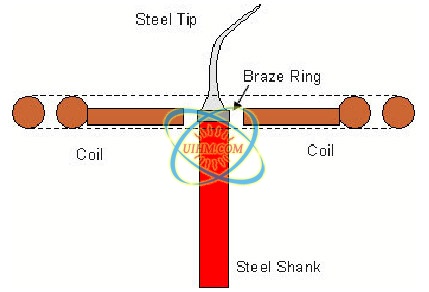

Objective To heat a steel tip and shank assembly to 1300°F (704°C) within 3 seconds for brazing with induction heating instead of torch brazing.

Material 0.1” (2.54mm) diameter steel tip & shank, 0.07” (1.78mm) diameter braze ring

Temperature 1300°F (704°C)

Frequency 278kHz

Equipment Power of 6KW induction heating system, remote heat station containing one 1.2 microfarad capacitor.

Process A two turn helical coil is used to braze the dental parts. The braze ring is placed at the joint area of the steel tip and shank.

Black flux is applied to the joint area. RF power is applied for 3 seconds to heat the parts to the established target temperature and the braze paste flows evenly and consistantly.

Results/Benefits Induction heating provides:

• Fast, accurate, repeatable heat

• Ability to heat very small areas within precise production tolerances

• Better joint quality, reduced oxidation

• Increased production rates and reduced labor costs

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment