Induction Forging Steel Horse Shoes

Views Send Enquiry

Objective To heat a strip of 1025 steel to 1800 oF prior to a forging process for the production of horse shoes.

Presently, blanks are cut and heated in a gas fired oven and then forged in the press.

With an induction coil in place, the steel would be fed continuously from a roll through the induction coil and into the forging press.

In order to meet the increased production rate, heating of the 13" steel section must occur within 10 seconds.

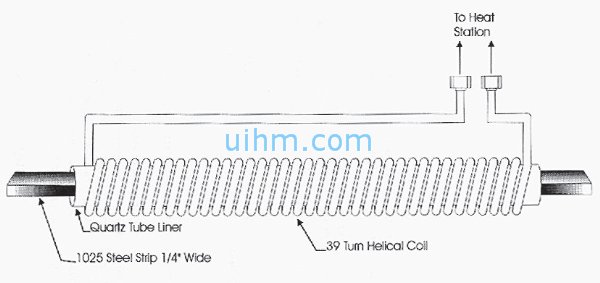

Material 1025 Steel strip approximately 3/4" wide and 1/4" thick.

Temperature 1800 oF

Frequency 15 KHz

Equipment UM-40AB-MF output solid state induction power supply including a heat station with a total capacitance of 0.5 μF.

Process UM-40AB-MF output solid state induction power supply was found to efficiently achieve the following results:

. 1800 oF was reached in 10 seconds.

. The production rate of 1 part every 5-10 seconds was met.

. The above results were achieved through the use of a 39 turn helical style work coil measuring 1 1/2" ID and 11 1/2" OAL.

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

induction heating steel plate by pancake induction coil

induction heating steel knife

induction heating steel pipes by water cooled flexible induction coil and 120KW RF induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater

induction heating steel plate

Hot

MF auto feed induction forging system

MF induction heater for forging work

induction forging long steel rods by MF machine

auto feed induction forging system

customized MF induction heater for forging steel rods

induction forging steel rods with series connection induction coil

induction forging steel rods by MF induction heater

induction forging steel rods

Newest Comment

No Comment

Post Comment