Induction Heating motor

Views Send Enquiry

Objective Heat steel to help bond an injection molded piece and help the reflow.

Material Steel motor body, 60 x 60 x 27 (2.4 x 2.4 x 1.1) mm(in)

Temperature 260ºC (500ºF)

Frequency 237 kHz

Equipment • Power of 20kW induction heating system, equipped with a remote workhead containing a total 1.5 μF.

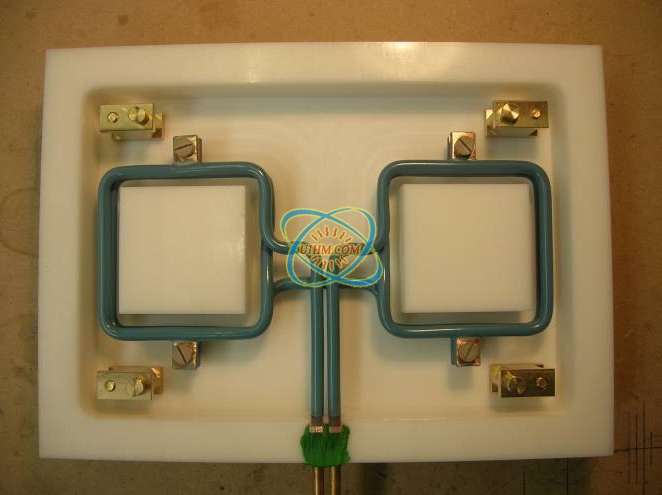

• An induction heating coil designed and developed specifically for this application.

Process/Narrative A two-turn binocular coil is used to simultaneously heat two steel motors prior to the injection molding process. This helps increase the bond strength between and reflow the plastic.

Results/Benefits Induction heating provides:

• Quicker process times with increased production rates versus a gas-fired oven. Ovens require long heat-up and cool-down times.

• Significantly reduced footprint

• Reduced handling due to location of the induction coil in proximity to the injection molding machine.

Heating motor

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment