Induction Melting Glass For Fiber Drawing

Views Send Enquiry

Objective To heat a metal susceptor vessel to 2200°F within 25 minutes for a fiberglass melting application

Material Metal susceptor vessel

Temperature 2200°F

Frequency 300KHZ

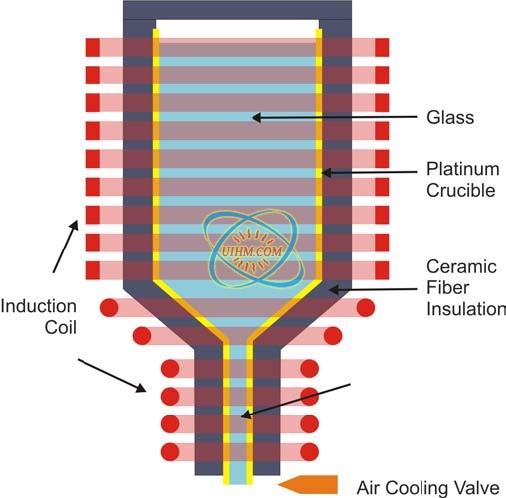

Equipment Power of 60 kW RF power supply, remote heat station and a specially-designed induction coil.

Process A specially-designed induction coil, shaped to conform to the metal vessel, was used to deliver uniform heat to the vessel. Initial tests were conducted to establish a heating pattern and time-to-temperature. RF power was applied for 22 minutes and the vessel reached a temperature of 2,200°F. An additional 3kW power supply was suggested for use when the glass in the vessel is emptied through the drain tube.

Results Uniform and repeatable results were achieved with the UIHM power supply and coil. The vessel can be maintained at 2200°F so that glass can be melted for fiber drawing.

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction melting with Titanium alloy pot by customized induction coil

induction melting silver wires

induction melting silver pieces

induction melting silver by MF tilting furnace

induction melting gold (2)

induction melting gold (1)

induction meling with strong magnetic stirring

induction gold meting

Newest Comment

No Comment

Post Comment