Induction Melting Titanium and Nobelium

Views Send Enquiry

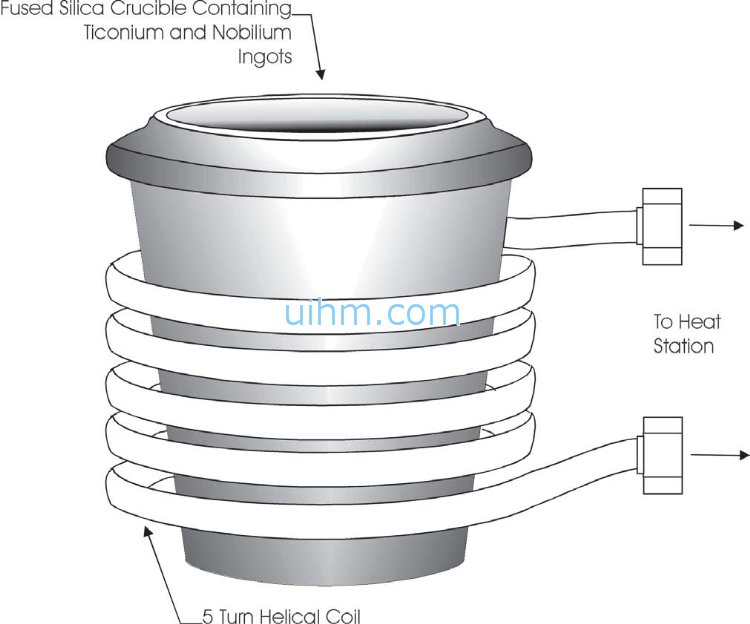

Objective: Crucible melting of Titanium and Nobelium ingots within a period of 45 seconds.Four ingots of Nobelium are to be placed in a crucible (ID#6012) and heated, while a single ingot of Titanium is placed in a crucible (ID#65045) for heating.

Material: 1/2" x 3/8" x 3/8" Ingots of Nobelium

1/2" OD x 3/4" long Ingots of Titanium

Temperature:

26500F (Nobelium)

26500F (Nobelium)

24500F (Titanium)

Application: Due to the small size of the ingots, MF induction heating was required to efficiently couple to the samples in order to provide the necessary power to initiate melting. By using the DW-MF-70 kW output solid state induction power supply and a five (5) turn helical coil, the following results were achieved:

35 seconds was required to fully melt the Nobelium Ingots.

30 seconds of heating time was required to melt the Titanium Ingot.

Equipment: 80kW output solid state induction power supply including four (4) capacitors totaling 1.33 μF, and a five (5) turn helical coil made from 3/16" tubing and measuring 1 5/8" ID and 1 1/2" high.

Frequency: 20KHz

Good

Bad

Related Content

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction melting metal sand after air cooled preheating

induction melting steel

induction melting silver

induction melting copper billets

Hot

induction melting with Titanium alloy pot by customized induction coil

induction melting silver wires

induction melting silver pieces

induction melting silver by MF tilting furnace

induction melting gold (2)

induction melting gold (1)

induction meling with strong magnetic stirring

induction gold meting

Newest Comment

No Comment

Post Comment