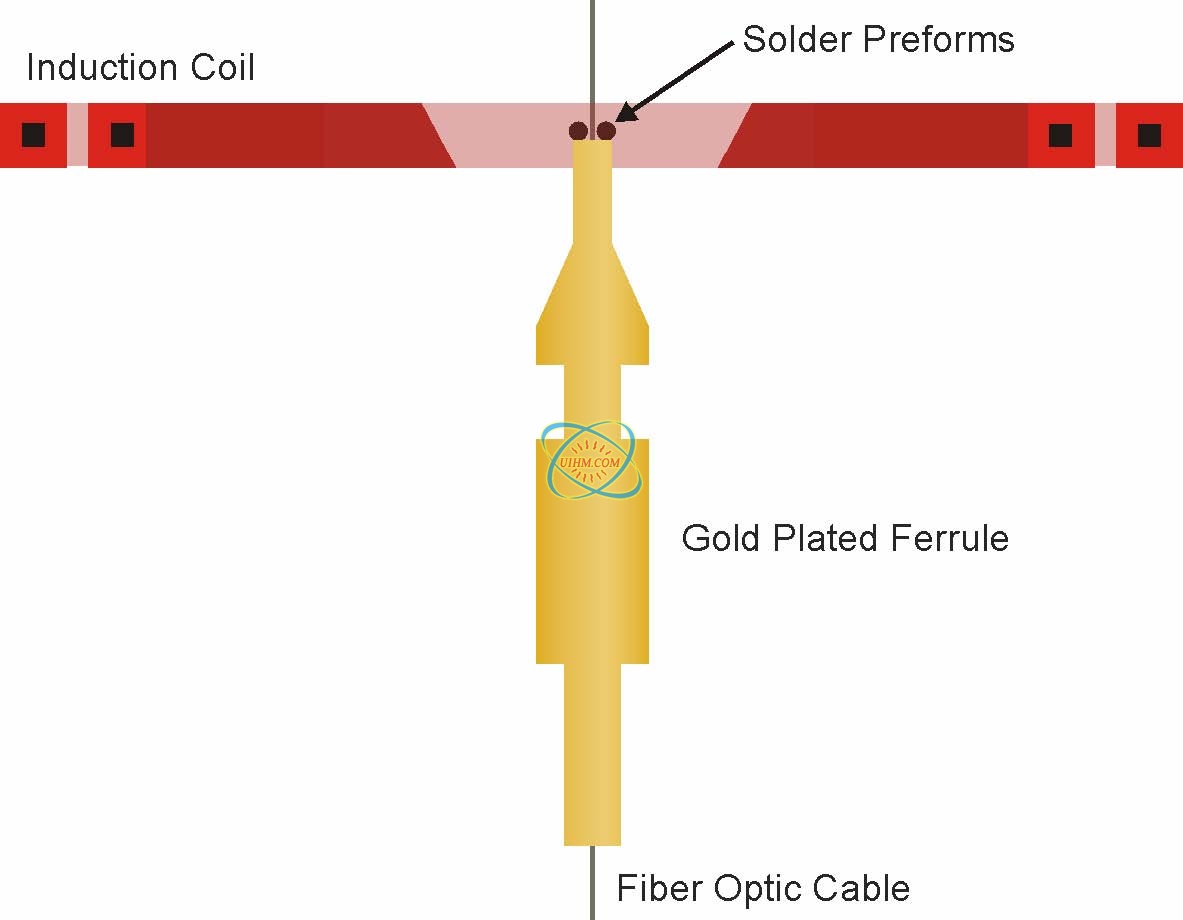

Induction Soldering Ferrule to Fiber Optic Cable

Views Send Enquiry

Objective To heat a gold-plated ferrule and fiber optic cable to 475°F within 8 seconds for a soldering application

Material Gold-plated ferrule tube, fiber optic cable, solder preform

Temperature 475 ºF

Frequency 270 kHz

Equipment Power of 6kW power supply with a specially designed induction coil.

Process A specially designed, two-turn plate concentrator coil was used to provide uniform heat to the fiber optic assembly. The assembly was placed in a specially designed fixture, then placed inside the induction coil. RF power was applied until the solder flowed and created a solid joint.

Results Consistent and repeatable results were achieved using the Power of 6 kW power supply and induction coil with a 5 to 7 second heat cycle, depending on the type of solder used (see solder chart below). Solder Heat Cycle

Soldering Ferrule to Fiber Optic Cable

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Newest Comment

No Comment

Post Comment