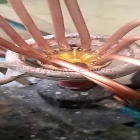

multi-heads induction coil for heating copper wire heads

Views Send Enquiry

↖ multi-heads induction coil for heating copper wire heads ↗

Advantage: heating speed is quick.

Disadvantage: need different induction coils for different motors as each motor / stator may have different wire heads for soldering, complex for changing induction coils.

Equipment: UM-20AB-UHF

PDF: multi-heads induction coil for heating copper wire heads

Good

Bad

Related Content

induction heating copper belt of electromotor

induction shrink fitting motor frame (2)

induction shrink fitting motor frame (1)

induction shrink fitting for D24cmX25cm motor frame to 350 celcius degree in 50 seconds by 60KW (4)

induction shrink fitting for D24cmX25cm motor frame to 350 celcius degree in 50 seconds by 60KW (3)

induction shrink fitting for D24cmX25cm motor frame to 350 celcius degree in 50 seconds by 60KW (2)

induction shrink fitting for D24cmX25cm motor frame to 350 celcius degree in 50 seconds by 60KW (1)

induction shrink fitting motor with rotating platform (double station)

Hot

induction soldering air conditioning evaporator splitter distributor by Phosphor copper brazing (4)

induction soldering air conditioning evaporator splitter distributor by Phosphor copper brazing (3)

induction soldering air conditioning evaporator splitter distributor by Phosphor copper brazing (2)

induction soldering air conditioning evaporator splitter distributor by Phosphor copper brazing (1)

induction brass soldering for AC parts

induction brass soldering connectors

auto induction brass soldering to SS-Steel

induction brass soldering by handheld flexible induction coil

Newest Comment

No Comment

Post Comment