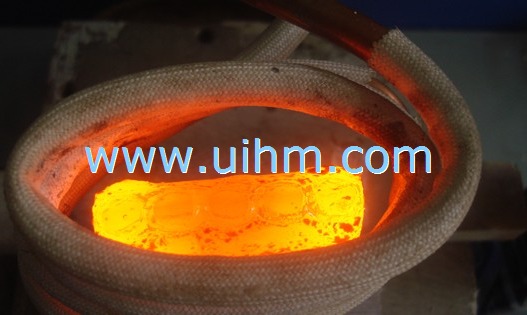

quick induction brazing

Views Send Enquiry

Induction Brazing temperature can be controlled from 500 C to 1800 C for most of the brazing applications.

Applications:

- Copper parts for compressors.

- Copper components of transformers.

- Brass components.

- Submersible pump rotors.

- Ring cable lugs.

- Aluminium component joints.

- Soldering of brass components.

- Steel components joints.

- Brazing of storage water heater Elements.

- Diamond tipped cutting tools.

- Carbide tipping of cutting tools.

- Optical Frame Brazing.

- Fuel pipe Brazing.

- Vacuum brazing of critical components.

- Brazing stainless steel orthodontic parts.

- Brazing of stainless steel to Brass.

- Rocker Pins.

- Hydraulic Hose.

UIHM induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke.

Features:

quick induction brazing

Related Content

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

induction brazing stator

induction brazing top of condenser pipes by pancake induction coil

induction brazing SS steel parts with auto feed system by UHF induction heater

induction brazing oil tube

induction brazing N type cable connector

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment