-

Keywords"blades",total

9 records

-

induction welding carbide circular saw blades

-

induction hardening screwdrivers blades

induction hardening screwdrivers blades

-

induction heating fan blades for welding

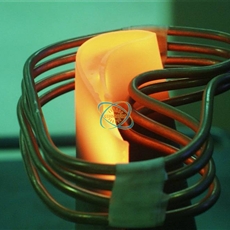

Heating fan blades for welding Objective To uniformly heat jet engine turbine fan blades to 1800F (982.2C) within five minutes for a welding applicationMaterial Jet engine turbine fan blades with 2”(50.8mm) length tipTemperature 1800F (982.2C)Frequency 21…

-

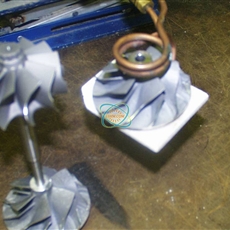

induction shrink fitting impeller blades to shaft

Shrink fitting impeller blades to shaft Objective Heat aluminum impeller blades to 200 F (93 C) and shrink fit onto a shaft.Material Aluminum impeller blades with a .28” (7.109mm) bore, aluminum shaftTemperature 200 F (93 C)Frequency 255 kHzEquipment • P…

-

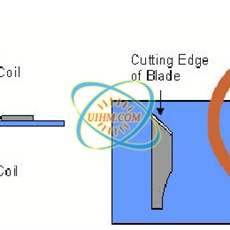

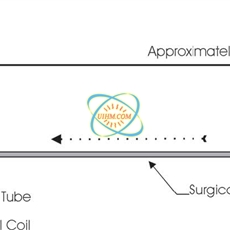

induction hardening surgical blades

Objective To quickly heat a steel surgical blade to 2000F (1093C) within 2 seconds so as to harden the blade edge. Material Stainless steel surgical blades, temperature sensing paint Temperature 2000F (1093C) Frequency 339kHz Equipment Power of 6kW ind…

-

induction hardening surgical knife blades

Objective Harden a 4″(101.6mm) section of a Stainless Steel surgical blade measuring 7″ (177.8mm) long. Hardness should be 48 to 53 Rockwell C on the blade after processing. Material 420 Stainless Steel Surgical Blades measuring 7″(177.8mm) long, 1/4″…

-

induction brazing turbine blades

Objective To heat an inconel turbine blade in a vacuum to 2000F and hold temperature for five minutes for a nickel brazing application. Material Inconel turbine blades, nickel metering plates, nickel braze Temperature 2050F Frequency 20 kHz Equipment A…

-

induction annealing saw blades

Objective Anneal saw blades used for cutting bread, prior to hole punching.Material .38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel.Temperature 600C (315.6F) for one secondFrequency 229kHzEquipment • UIHM 6 kW i…

-

induction brazing turbine blades

Process The UIHM ABS Mark 2 with a vacuum level of <510-4 torr was used for the testing. A specially designed induction coil was used to provide optimal heating (approximately 80% energy efficiency) to the braze joint area. The temperature of the joint …