Temple por inducción

Views

- Intro: Endurecimiento por inducción templado inducción es el proceso de endurecimiento de acero por calentamiento. Se realiza mediante un campo magnético alterno a una temperatura por encima o dentro de un intervalo de transformación espe…

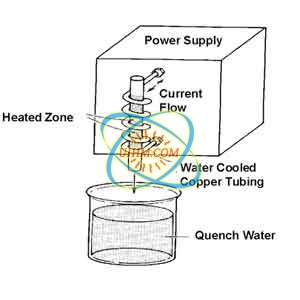

Induction hardening is the process of hardening steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of hardening can be specifically applied to both full as well as surface hardening methods. This is the kind of heat treatment process in which the metal part is heated and later it is quenched. The metal which is quenched further undergoes a martensitic transformation in order to enhance the hardness and brittleness of the specific part. Principal Techniques:This hardening process can be performed mainly by two procedures:Traverse HardeningSingle-shot HardeningIn the traverse hardening systems, the work piece to be worked on is repeatedly passed through the induction coil and a quenching spray is being used. It is majorly used in the production of some shaft type components including steering components, drive shafts and power tool shafts etc. The quench ring that is being used can also be an integral component. This method is also applicable in the production of edge components such as: hacksaw blades, leather knives, paper knives and lawnmower bottom blades.In the single-shot hardening method the component which is to be treated is held statically or is rotated inside the coil in which the complete area is being heated for a particular time which is pre-set. This method is generally used for edge hardening of complex shaped tools, flat face hardening of hammers and for the production of small gears. Requirements for Induction Hardening:As far as this heating procedure is concerned, three things which are majorly required for this process to occur are as follows:1.A high frequency electrical power source2.A work coil to generate the alternating magnetic field3.An electrically conductive work piece which is to be heatedBefore this heat treatment process is performed, it is necessary to make a note of the chemistry of the metal, the adjustment of the temperature of the metal and last but not the least the characteristics of the metal. Tips for Successful Induction Hardening of Steels:The selection of steel plays a vital role in this heat treatment process. Steel parts are mainly hardened to get hold of some specific properties such as wear resistance, tensile and fatigue strength. Moreover, it can either be done on a specific part of the work piece or throughout the entire part. The procedure involves heating the work piece to a temperature which is higher than the austenitizing temperature and then the steel is allowed to cool at a rate which is fast enough to transform it to fully martensitic structure. These hardening service providers must have a license which states that these are authorized to perform the different types of heating treatments and the company or the service provider must use the right equipments and procedures for hardening.

We are blessed with a number of improved and useful devices and systems that have changed our life. From health, education, communication to entertainment, science and technology has touched every area. Health industry is witnessing a lot of improvements as a result of the introduction of scientific interference. Now, it has become easy to treat some of the problems that doctors could not handle in the past. The process of induction hardening is almost similar to any other heat treating operations. It is mainly performed to harden parts. The procedure is dependent on various factors to be successful, adjusting the temperature of the material, the general ability and chemistry of the material to harden, proper cooling of the material so that the transformation of the martensite can occur. When one or more than one of these critical characteristics are not present, the material may remain soft entirely or it may end with soft spots. So, it is very essential to check whether all these factors are present or not. Most of these factors help in quenching and heating of the parts. There are different types of heat treatment processes, including Annealing, Ageing, Hardening, Induction Annealing, Carbonitriding, Case Hardening, Carburising, Induction Hardening, Stress Relieving, Shot Blasting, Shot Blasting, Normalising and Tempering to materials like Cast Irons, Alloy Steels, Stainless Steels, Die Steels, Tool Steels, Carbon steels etc. Ageing is the process that causes structural change. It may occur in certain alloys and certain metals at atmospheric temperature or at higher temperatures (also called as artificial ageing). As a result of ageing, the hardness value and maximum stress are increased. You should make it sure that there is some reduction in ductility. Artificial ageing is a process in which the ageing is created by heating at high temperature. It results in precipitation hardening. It is one of the best heat treatment processes. It is quite essential to adjust the temperature of the material so that the austenitic phase can occur. In certain cases, based on the material, it may be essential to hold the temperature for a certain amount of time. It is done to allow the material to avoid undesirable by-products and also allow to fully transforming. There are many other types of heat treating operations that are used. Annealing, Carbonitriding are two of the popular heat treating processes. Annealing is a process in which steel is heated and then the temperature is adjusted properly. Then the cooling is done at a suitable rate, with machinability, with the object of improving softness, of obtaining a desired structure and of removing stresses and cold working properties. Generally the steel is heated to a certain temperature at which carbide is partly or fully taken into solution.

Induction hardening is a very widely used industrial process for the surface hardening of steel. The steel components to be hardened are heated by means of an alternating magnetic field to a temperature within or above their transformation range. This heating process is then reversed by immediate quenching or rapidly cooling down the metal components to room temperature. Just as with case hardening or face hardening the core of the metal, the component remains unaffected by the treatment and its physical properties and advantages are unaffected too. But it is now sheathed in a much harder alloy that has a higher carbon content.The process requires a source of high frequency electricity that is used to drive a large alternating current through a coil. The passage of current through this coil generates a very intense magnetic field that is rapidly changing in its polarity in the space within the coil. The metal component that is to be hardened is inserted into this rapidly alternating magnetic field and the current generated within the object itself rapidly heats it up. This hardening results in a layer of a highly wear resistant alloy around the component. This makes these sort of metal pieces used widely in automotive and industrial applications where long life and wear resistance are required.There are two primary types of hardening. Single shot or static hardening is the process where the component is contained within the coil in its entirety and either held static or rotated. The hardening effect is achieved all over the surface of the object simultaneously. The advantage is a quicker process due to the fact that the entire component is being treated in one go itself. The quenching process or the cooling down is also done at one go for the entire component. The drawback is the higher power requirement of the induction coil required for the hardening process. Traverse hardening is the other type of induction hardening process widely used for long components like axle shafts and steering columns for automotive applications. The induction is actually done by a ring type inductor that creates a band of heat that needs to be moved along the length of the component. el proceso de enfriamiento también se realiza de manera similar. La ventaja es que se requiere menos energía y variando la velocidad del anillo de endurecimiento variable es alcanzable. El inconveniente es el tiempo adicional por componente.

Con el desarrollo de la ciencia y la tecnología, se han introducido una serie de sistemas y dispositivos innovadores y mejorados. De entretenimiento, salud, comunicación para viajar, cada arena ha sufrido un cambio. Este rápido crecimiento también ha llevado a la introducción de Temple por inducción, un método de calefacción eficaz y útil. Temple por inducción se realiza generalmente para endurecer piezas metálicas. Sin embargo, hay ciertos factores que desempeñan un gran papel para hacer esta calefacción proceso exitoso. Su esencial tomar nota de la química del metal, la regulación de la temperatura del metal para que pueda ocurrir etapa austenítico, las características del metal así como su capacidad para enfriar muy rápido. Cada uno de los mencionados factores son esenciales para este proceso de endurecimiento. Si alguno de estos factores está ausente, el metal no podría endurecer o partes blandas puede ocurrir en el metal. Estas características importantes o factores tienen gran control sobre la calefacción o el enfriamiento del metal. Sin embargo, no sólo inducción endurecer procedimiento que ayuda en el tratamiento de la calefacción de metales. También hay otros tipos de métodos como el recocido, Temple, revenido, carbonitruración, inducción de recocido, Temple, homogeneización, caso endurecimiento, tiro de voladura, normalización, etc. para aliviar el estrés a los materiales como arrabios, aceros al carbono, aceros de morir, aceros, aceros de herramientas y aceros inoxidables de la calefacción. Amortiguamiento es una parte muy importante para conseguir la dureza deseada de un metal. Enfriamiento inadecuado puede llevar a una variedad de problemas. El uso de un mal Temple para que un metal específico podría ocasionar el proceso de enfriamiento para llegar a ser lento. Por lo tanto, es importante revisar si derecha y una amplia cantidad de Temple se utiliza para quitar el calor o no. Polímero es utilizado principalmente por la quenchants a base de agua. Básicamente, el uso de se ralentiza el proceso de enfriamiento y previene la aparición de grietas. Sin embargo, incluyendo demasiada cantidad de polímero no es una idea inteligente. Este compuesto químico puede reducir el calor capacidad de extracción y causar el metal permanecer suave. También revisa si el elemento es enfriado correctamente o no o de lo contrario el calor residual altere el metal. Proceso de endurecimiento de inducción se utiliza principalmente para las aleaciones de acero. Este tratamiento de calefacción principalmente pretende mejorar la vida de comportamiento, durabilidad y fatiga desgaste de metales y aleaciones, que generalmente se utilizan para hacer resortes, engranajes y ejes. Es sólo las organizaciones de profesionales de tratamiento térmico que tiene el perfecto configurado y conocimiento para ofrecer a la derecha. Estos son algunos consejos que te ayudarán a encontrar un experto en el servicio de tratamiento térmico. El endurecimiento proveedor debe ser Licenciada y autorizada para realizar los diferentes tipos de tratamientos de la calefacción. La compañía que opta debe proporcionar servicios de calidad. Por lo tanto, es importante conocer los últimos registros de la empresa en relación con el tratamiento de la calefacción. Averiguar si la empresa utiliza los equipos de la derecho para endurecer. También, tener en cuenta la experiencia de la calefacción de inducción de UIHM de la compañía en ofrecer servicios de endurecimiento metal eficiente y segura. Sin embargo, compare los precios de los proveedores de diferentes servicios en esta industria y encontrar la mejor oferta en línea.

endurecimiento de inducción

Tags: Induction Hardening

Recommended

Información de base de Calefacción inducción de alta frecuencia

Inducción principio de calentamiento

Glosario de Términos de calentamiento por inducción

Como elegir calentadores de inducción

Calentador de inducción de IGBT perfiles

¿Cómo funciona Soldadura por inducción

¿Por qué es mejor soldadura por inducción

¿Qué es el calentamiento por inducción?

Newest Comment

No Comment

Post Comment